Last meeting

![]()

President Bill Henzel opened our July 19 meeting as a Special Meeting. The purpose of the meeting was for the membership to consider an addition to our By Laws of language that the IRS wanted to further our application for a 501(C)(3) tax exemption classification. The proposed language was included with the July newsletter and read at this meeting. As Bill explained, this exemption would make it easier for us to get meeting space since many organizations required it. In addition, it may help us secure favorable rates for insurance. There was some discussion and questions. Then the proposal was moved for adoption, seconded and approved unanimously.

Following the Special Meeting, the regular meeting started with Bill making some announcements. Mark Ferraro has donated a LCD projector to the club so that PowerPoint presentations can be made. Bill thanked Mark for a very generous donation which will save the club a lot of money. We were seriously considering buying one. The projector was used by our presenter later in the evening.

Woodcraft is having a Faire on Friday and Saturday September 28 & 29. BAWA will have a booth and a staffing sign up sheet is being circulated. Following last year's disaster where our booth sat empty, we must staff the booth this year. Woodcraft has been very good to us in providing space for some of our meetings. There was a partial sign up but many more volunteers are needed. The sign up will be again circulated at the August. We need full participation.

Per Madsen announced the schedule of future meetings. We will have our September 20th meeting at Joe Brown's Distinctive Woodworking shop in San Carlos. The annual box contest and jigs & fixtures demonstration will be held during the November 15, 2007 club meeting.

With the absence of our Rafflemeister Stan Booker, there was no raffle or door prizes. Stan is on a world tour with his ill gotten gains from the raffle. Hope you are having a nice time, Stan.

Yeung Chan will be conducting a workshop on either Nov 3-4 or Nov 10-11. A sign up sheet is being circulated.

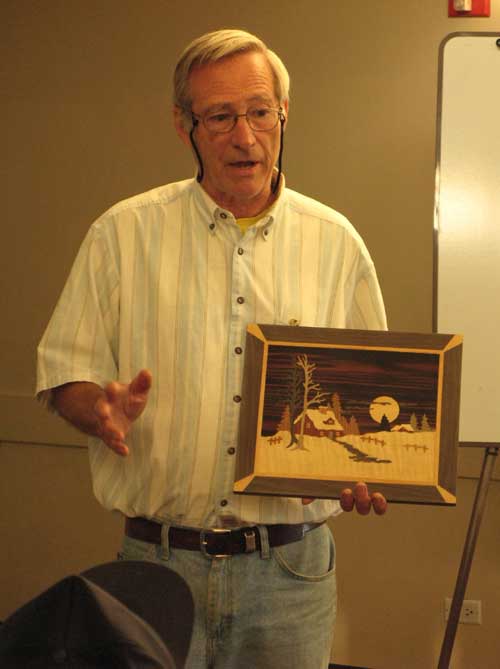

Ken Horner, out guest speaker for the evening, announced that the Marquetry Club meets every Tuesday evening and one Saturday a month at the Sawdust Shop in Sunnyvale. Guests are welcome. Ken showed us two of his pieces: a landscape featuring reflections in ebony, elm and walnut; and a turned bowl with a marquetry scene inset into the bottom of the bowl. He briefly described the procedure to make the items and although they looked involved, he said it could be done in a weekend.

A Tech Talk was next. Bill Henzel confirmed the rumors. He has finished constructing and configuring his new woodshop. The project started out as an effort to simply remodel the existing garage to accommodate all of his tools. Yielding to the superior wisdom of his wife who wanted a laundry area in the garage, Bill accepted her proposal to build a free-standing shop structure in his large backyard. Bill designed the shop and did almost all the construction, except for pouring the 6" reinforced concrete slab floor. Framing was simplified with the use of rolling scaffolds, adapted with block and tackle to create a crane apparatus, easily hoisting heavy glue-laminated beams into place.

The building is designed with two dormers so that natural sunlight illuminates the shop. The back wall is 10 feet in height, facilitating vertical wood storage. He built a bathroom in the shop. The shop has 100 amp electrical service and is well insulated, thereby reducing heating costs and external noise. The front door was originally intended to be a sliding barn type door. However, these doors are prone to leak in heavy winter rains. So, Bill changed the framing to accommodate a roll up garage door. But, it just didn't look right and he would have lost overhead space and the design changed for the third time. And as they say, the third time is a charm. The final door design includes a six foot wide French door and full length side windows. An Oneida 2 hp cyclone dust collection system is installed in the shop. Oneida designs the layout for free when you purchase the system. Because Bill did most of the work himself, he was able to keep his costs way down. He built a 760 square foot shop for approximately $35,000, or $46 per square foot. Bravo Bill.

Bill's suggestions for others who are thinking of tackling this kind of project:

- Use lots of ladders and scaffolding

- Take your time

- Safety precautions are never a waste of time

- Know your local building codes

Bill will be hosting a Toy Workshop in his new shop in the near future.

Book & Movie Reviews, a new talk to add to our Tech and Tool Talks was by Dan Goodman, our club librarian who recently acquired the Sam Maloof DVD. He had the opportunity to watch the DVD before the 25th Anniversary Dinner at which Sam Maloof was our guest speaker. His comment --- "Sam did a great job of making me feel humble." The DVD explains how Sam picks his wood, organizes his shop and shows Sam's unique bandsaw techniques used to create joinery and furniture. Dan recommends this DVD.

Bill Henzel briefly reviewed Router Magic by Bill Hilton. He found two chapters particularly useful: Dowel Making and Router Lathe.

Show & Tell was next with Arnie Champagne showing new doors he is making for his house from salvage old growth Douglas Fir. The wood is quarter sawn and he pointed out that he made the tenons too large and with flat sawn wood. He would have made a better joint with smaller, quarter sawn tenons. One member observed that he could have made the tenon with plywood. Arnie uses Space Balls to center the door panel in the ¼" dados.

John Blackmore showed a prototype of a backgammon board he is building for a member of the Pacific Union Club in San Francisco. The board has removable back panels so that the cork playing surface can be easily replaced when worn down. Secure fixation of the back panels is achieved with a lipped edge fitting into a groove of the frame and with brass screws going into threaded brass inserts. The final boards will be made with quarter sawn White Oak harvested from the client's property. He also mentioned that if anyone ever has a chance to go to the Pacific Union building, the woodwork there is spectacular.

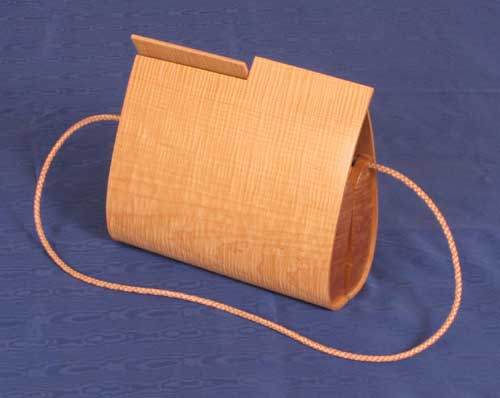

Jamie Buxton stole the Show & Tell. Jamie made a shoulder carried purse from molded Maple plywood, seven layers thick. He carefully laminated and molded the plywood in a clamshell like shape using a vacuum molding process. The shell halves are joined at the bottom with a concealed piano hinge. Rare earth magnets are used to clasp the top closed. A braided shoulder strap completes the purse. The finish is a wipe-on varnish. It is a beautiful piece of work. Too bad there is only one. However, Walmart has ordered 10,000 and he has contracted to have them made in Inner Mongolia where costs are much lower than Jamie's expensive living costs.

After a break where coffee, tea, cold drinks and cookies were gobbled, the meeting resumed with a presentation of our guest speaker.

Guest Speaker: Ken Horner is a retired organic chemist who lives in Sunnyvale, the heart of Silicon Valley. He is active in several local woodworking clubs including the South Bay Woodworkers' Association and Marquetry Club. He has written three books: Woodworkers Essential Facts, More Woodworkers Essential Facts and the soon to be released Essential Guide to the Steel Square, published by Cambium Press.

Ken's topic this evening was "How to Get Published" or, "How I Made Boring Math into Two Interesting Books for Woodworkers with a Third One on the Way". In the late 1990s, Ken wrote a series of short essays on shop math and circulated it among his friends in the South Bay Woodworkers' Association. It had 18 sections and was oriented towards the practical uses of math in everyday woodworking. Readers greeted the pamphlet with enthusiasm and Ken decided to see if he could find a publisher if he were to make it into a book.

He put together a Letter of Inquiry package, essentially a one page synopsis covering the following:

- title and idea summary

- description of the need

- competitive titles

- example of his writing and drawings, and

- table of contents

In November of 2000 he sent the package to 14 publishers. Seven rejected the offer and seven ignored it. One publisher gave him a glimmer of hope. Math was too boring to readers, perhaps another angle could be found -- rules of thumb for the woodworker using mathematical principles. Ken was invigorated and reworked his idea and outline. He sent the new Letter of Inquiry package back to John Kelsey who accepted the idea. Then negotiations began on a contract. He signed a contract in 2002, agreeing to write 25 chapters in 6 months. And what was his reward -- a paltry advance and future royalties. Ken finished the book on time and galley proofs were sent to the Woodworking Book Club, expecting maybe to sell 500 copies per year. To his surprise, the book club made his book their monthly selection in June 2003. Woodworker's Essential Facts, Formulas and Short-Cuts became the book club's most successful selection, selling over 9000 copies in the first printing. The second printing was for an additional 5000 copies. The book is now in its 4th printing. The printer, Cambium, sold over 3000 copies.

Following on the success of the first "Essentials" book, Ken was persuaded to write his second, More Essential Woodworkers' Facts. In the Spring of 2006, Woodworkers' Book Club made it their selection of the month and ordered 12,000 copies. The reward did not change, still a paltry advance and future royalties.

Due this fall is Ken's third book: Essential Guide to the Steel Square. In this book, Ken follows the same rule of thumb format to explain how to use the versatile and frequently forgotten steel, framing square. It is a veritable hard goods computer.

- Ken offered several useful rules for aspiring book authors:

- Pick something familiar to you

- Know who you write for and who will buy the book

- What is the competition out there

- Why will your book be better

- Ask yourself—can I write, do I have the time

- Who will do the pictures and drawings?

- Does the publisher have to involve another party?

- Submit your copies to the publisher using MSWord and email

- Will you self publish, or find an established publisher. He recommends the latter.

In conclusion, Ken demonstrated the usefulness of the books by describing one chapter from each of his three books. Proportions and the Golden Rule can make your furniture designs successful. Wood Strength influences wood compression, shelf stiffness and deflection and ultimately the shelf design. The steel square can be used to determine the ratio of drawer sizes to fit a bureau carcase. With each example, he provides a rule of thumb where very little math is involved. A very ingenious system which is why it got the attention of many woodworkers.

At the end, we were inspired. No longer need we fear math. Simply follow the Rules of Thumb and we could figure it out.

John Blackmore & Mark Rand