Last meeting

![]()

Craig kicked off the meeting with Announcements. He mentioned that Woodcraft was going to have a special NO SALES TAX day on June 26th. He thanked Mike Yoder for doing the evening's refreshments. He reminded everyone that there will be a NAME TAG contest at the July meeting. Anyone who doesn't have a real home made wooden name tag will be banished from the club and forced to join the Underwater Basketweavers of America club. He also mentioned that if you want to be stylishly dressed, you could buy either a short sleeve tan shirt or a blue long sleeve with the club name and your name (doesn't replace the wooden name tag) also a cap from Jay Perrine. Jay mentioned that he needs an order of about a dozen shirts before they can be made. A show of hands wanting a shirt showed about a dozen interested members. He also said that Stan Booker is traveling so the raffle and the door prizes will start up again next month. Harold Patterson said that there would be no toy workshop in June. He also passed around a race car that will be made at the next session. Also, the articulating toys will be completed at the July meeting. Arnie Champagne is going to school at the College of the Redwoods for six weeks. He mentioned that members should come up after about the third week to see what the students are working on. Richard Winslow reminded everyone that he can take orders for items from Crafts Supplies. They deal primarily with woodturning items but have other things as well. Most items are discounted but the percentage varies. So if you want an item contact Richard and pay him the full price. When the item arrives he can see what the discount is and reimburse you. Jay made the suggestion that the hats be bought by the club.

Moving right along, we then had Show and Tell. Bruce Woods showed two jewelry boxes he made for his daughters. The first box was made of Bird's Eye Maple and Bubinga with a Cedar lining. The second box, made of Sapele was finished with varnish and had a magnetic latch.

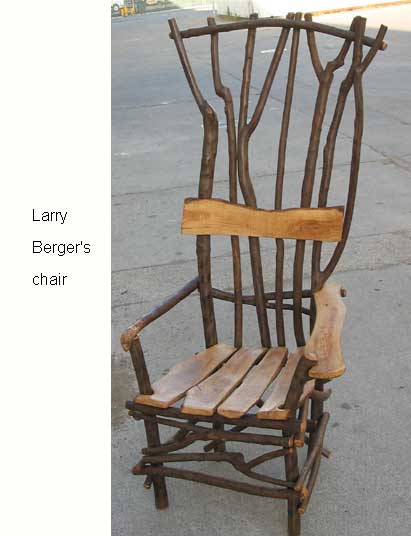

Arnold Champagne brought in a commissioned round table made of quarter sawn Cherry. It was built to incorporate the owners' Persian forged metal top depicting family history. Arnie laminated the Cherry skirt for the table, set the tenons at 6 degrees and used Ebony accents. He purchased the four spiral turned legs. He used a West Marine System 205/106 adhesive system that allows 6-24 hours of set time. Eric McCrystal displayed the mock-up of a cabinet case he made in Arnie's class. Larry Berger enjoyed the meeting sitting in a bent stick chair he made. Made of hedge wood and Olive, it took 4 hours to make. Sticks were jointed with self tapping screws set in drilled, countersunk holes. It was finished with wax.

The next item was for visitors and new members to introduce themselves. Simon Schwartz who became a member as a gift from his wife, Mick Friends, Bruce Hartnick, Jeff Jensen and Leslie Comstock.

After a very satisfying break, we were introduced to the main speaker and our host for the evening Leon (Leonidas) Kyriakopaulos. He introduced himself as an impatient woodworker who has found that he can control his schedule using big, old, well-made American woodworking machines. They were produced in the period from 1920 to about 1965. He announced his irreverance for the Krenovian, Maloofian and Nakashimaian philosophies of woodworking saying he had never seen the soul of a tree. He has, however, made many fine pieces of furniture, pointing to a large nearly 10 foot diameter table now under construction that incorporates his geometric patterned wood pieces. The pieces are inserted to replace defects in the wood, a practical, not philosophical consideration.

He is, in his own words, a tool junkie of American woodworking equipment. In 1900 he said there were 110 American companies making woodworking production equipment, including such names as Oliver, Yates American, Berlin and Woodlin. He thinks the Yates American Y-36 is the finest bandsaw ever made. He started collecting woodworking equipment while he was attending Cal on a ceramics fellowship. His teacher and mentor introduced him to used equipment by taking him to auctions of tools on decommissioned U.S. Navy ships. On one of his first trips, he bought a Neuman 12" jointer for $1500 and an Oliver 24" planer for $1000. On the same day, he resold the machines for $2000 each. He was hooked. When ships came in to be scrapped, he would get the call, go to shipyard and buy machines, keeping the best ones for himself. He continued the process and kept trading up. He developed a knack for it, creating value in the process. He bought an Oliver 2260 pattern mill and tools for $7500, one of 22 made in the 60 year history of the company. It has five speeds, has a rotary table that goes out 10 feet. It cost $26,000 new and the tools were originally priced at $12,000. He looks for value -- machines allow him to do things no one else can do. Even the purist woodworkers come to him to get special jobs done. He says "if you don't pay too much for a machine, you don't have to use it."

He showed us a series of laminated wooden balls he makes on an Oliver lathe using special tooling he had developed. He makes them well and he makes them fast. He designs woodworking pieces around these unique balls. He encouraged everyone "to go one step beyond in design to bring out the dark side" of your character.

His shop is in an old converted jet engine shop on the old Naval Air Station Base. On tour, we saw his shop, the production shop, the paint rooms, the machine shop and several smaller shops occupied by other woodworkers. In his production shop, he showed us an Orton D1 36" planer made in San Francisco during the building boom of the early 20's. It weighs 8000 pounds has a 25 hp motor and can take off ¼" of wood in a single pass.

Leon offered to help anyone who wants to buy old woodworking equipment. If you run across something of interest, he is available to offer information and advice. He distributed his list of available equipment. He is always interested in buying old equipment and catalogs. If you bump into something, call him. He said old Dewalt single phase radial arm saws can be found for about $200. He says the top bandsaws are Yates, Tannovitz and Oliver.

One of his woodworking safety tips of note is to wear a leather apron -- kickbacks will not penetrate the leather. He always wears one himself. He also suggested woodworkers consider getting a scissor lift for their shops. Then one can work at any convenient height. Lifts can be found for about $200.

The meeting adjourned with many members wondering how they can build bigger shops and get three phase power.

John Blackmore & Mark Rand