Newsletter October 2024

BAWA Hybrid Zoom Meeting October 20, 2024

The meeting was called to order by President Frank Ramsay.

Frank announced that he will resign as BAWA President at the end of this year as he does not want to drive to and from Foster City on dark, wet, winter nights and thinks that the President should attend most in-person meetings.

Bruce Powell is resigning as Membership Director, and Frank was willing to take on that role including Communications and the BAWA website.

Paul Krenitsky announced that he would be willing to take on the roll of President, if someone would be willing to take on the job as Program Director.

Jon Kaplan will continue his role as Treasurer and Burt Rosensweig will continue as Secretary.

Laura Rhodes will once again take on the formidable task of organizing the BAWA Annual Woodworking Show.

The meeting was called to order by Frank Ramsay.

Program Announcements – Paul Krenitsky

November: Annual Members Meeting plus Speakers from the Mission Community Woodshop.

December: Ornament Challenge, Members bring in jigs and fixtures while we will have the Annual Holiday Party Potluck

Other announcements

Max Goldstein has a sturdy woodworking bench for sale. (please contact him directly: maxgoldstein1@gmail.com)

He also donated two back saws to the Palo Alto Adult School Woodshop.

Featured Speaker

Tonight's First Speaker: Lloyd Worthington-Levy

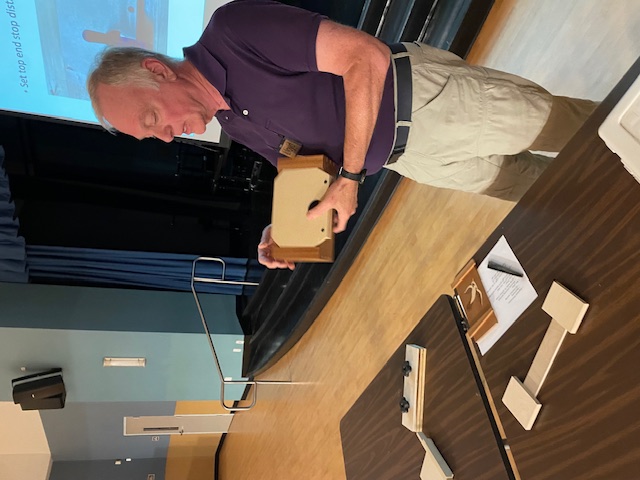

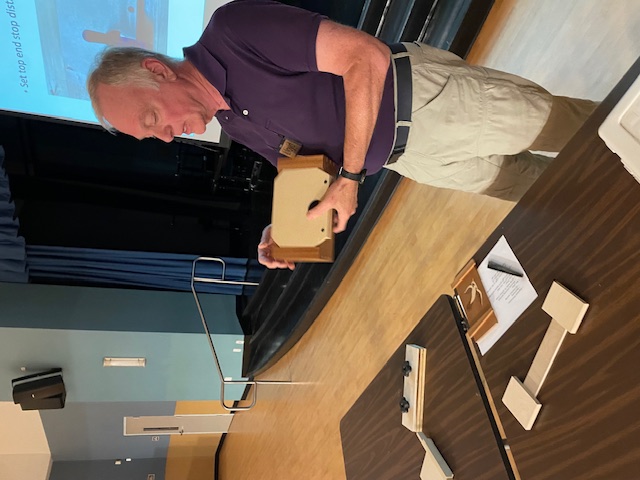

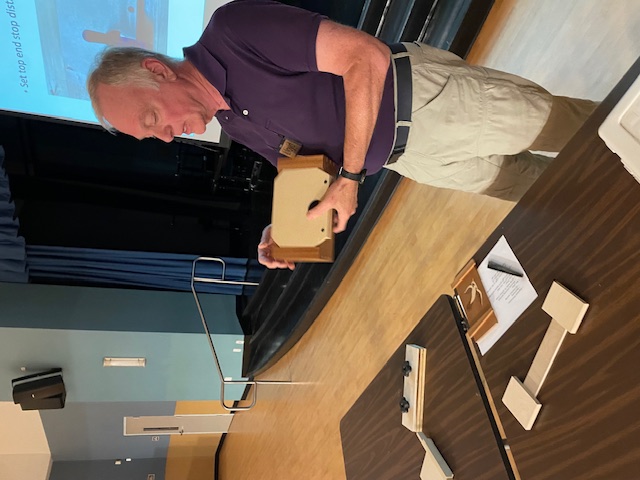

Lloyd described the process of making multiples of his Japanese Toolbox.

He bought an iGaging digital readout for his thickness planer that enabled him to dial in the exact thickness required wants.

(Editor's note: I have two of them on my desktop milling machine)

He cuts dovetails on his tablesaw using a sawblade with a 7 degree bevel on top to match the angle of the dovetail. (Available them from Forester for about $234)

Lloyd made 3D printed spacers/stop blocks for cutting the dovetails that way he could get repeatable distance between dovetails.

Knowing how important it is to assemble the box squarely, he made a fixture to hold the walls square during glue up.

The top is held in place with a wedge and opposing tapers using 3D printing

Lloyd made a jigs to hold the wedges at the correct angle on the table saw plus another one to position the wedges on the box top ane a final wedge is made longer than needed and trimmed to length after all other pieces are assembled.

Toolbox build: Newsletters/Newsletters2024/Pictures_October2024/Japanese Toolbox build compressed.pdf

Tonight's Second Speaker: Jamie Buxton

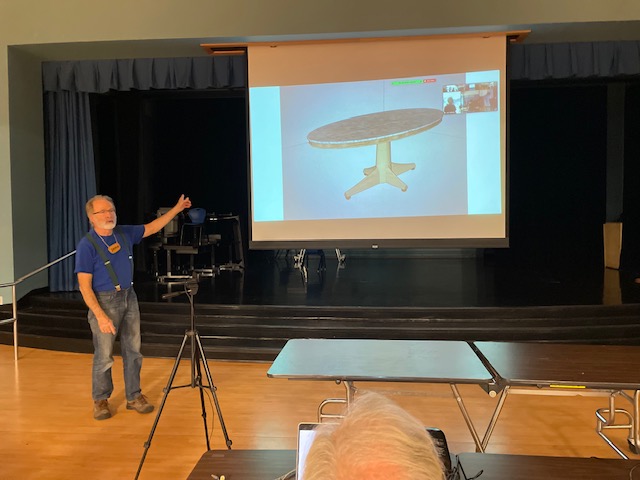

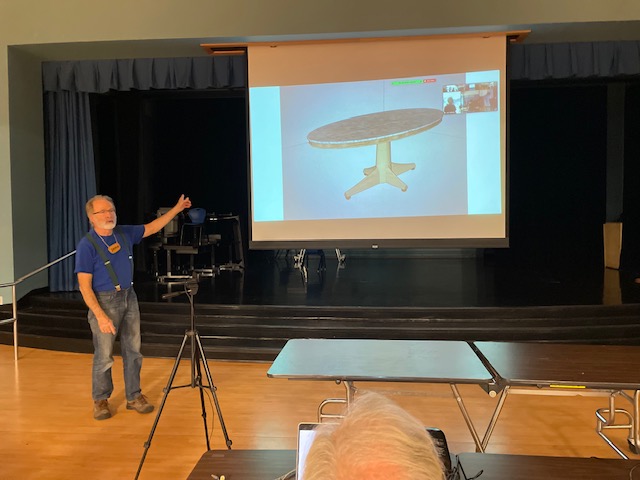

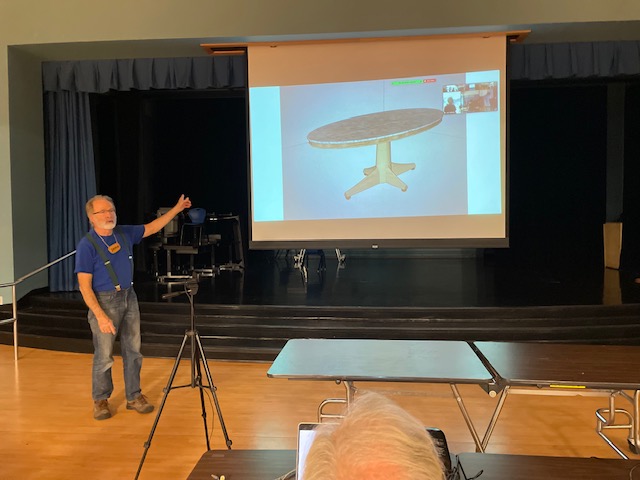

Jamie talked about the dining table he was commissioned to make for a client who had an 150lb. oval marble top but no base.

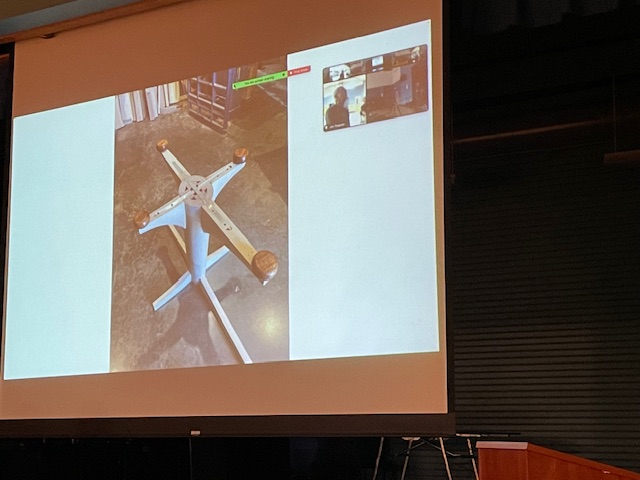

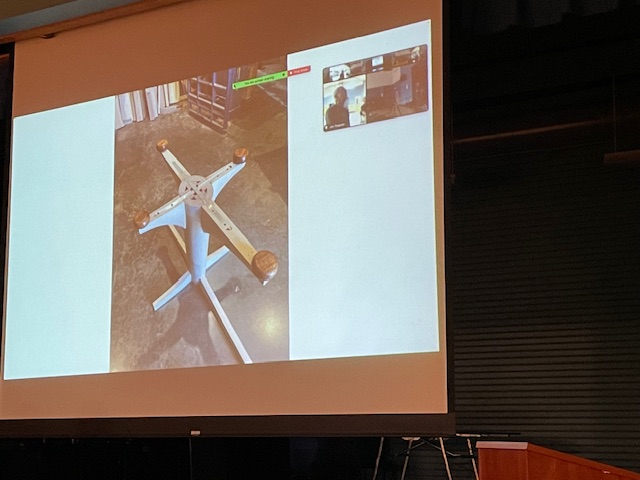

Base with supports

He made a wood base with Curly Maple on the outer edge of the oval below the marble top.

The central support post is made up of 8 pieces glued in an octagon. Each piece started out as 8/4 lumber. This tapered post was shaped into an oval using the jointer, the hand plane, and finally the random orbit sander.

He made stub tenons to attach the top support arms to the post and the same for the legs at the bottom of the post.

An angle grinder was used to rough shape the legs which have a half oval cross section. The leveling feet were made Khaya with 3/8in. threaded rod to attach the leveling feet to the bottom of the legs. 0.10 thick veneer was used to cover the outside edge of the wood that appears below the marble top.

Unfortunately the customer dropped and broke the marble top before the project was finished, so Jamie was tasked with creating a nice wood top to replace the marble.

Jamie bought Curly Maple boards and cut them to 0.10 inch thick so he could make a nice laminated top.

The Curly Maple vacuumed to a plywood base.

He made a MDF template to match the shape of the marble top base. The template was then used to cut the Curly Maple / plywood to shape.

It was also used to cut the Khaya surround to shape. He made two jigs to attach to his router to allow him to cut the inner and outer matching edges.

The finished table

The Curly Maple top is surrounded by a Khaya ring. He added a 3/16in. thick band between the Curly Maple and the Khaya outer. The base is protected with a sprayed on acrylic finish and the top is protected with wipe-on varnish. I am sure the customer will be happy with the finished product - it looks gorgeous.

2x4 Challenge

Max Goldstein

Max brought in a box with a hidden compartment. No one could figure out how to access the hidden compartment until he demonstrated the technique.

Laura Rhodes

Laura Rhodes brought in a box frame with four angled sides. She was trying to learn how to hand cut dovetails on a box with sides that are not vertical. She found it to be very difficult. She also wondered about hand cutting the groove for the box bottom, when the sides are not vertical.

Jon Kaplan

Jon brought in a 2x4 sculpture that was made up of very short pieces of 2x4 end glued. Laura said it looked like a DNA molecule.

Tom Gaston

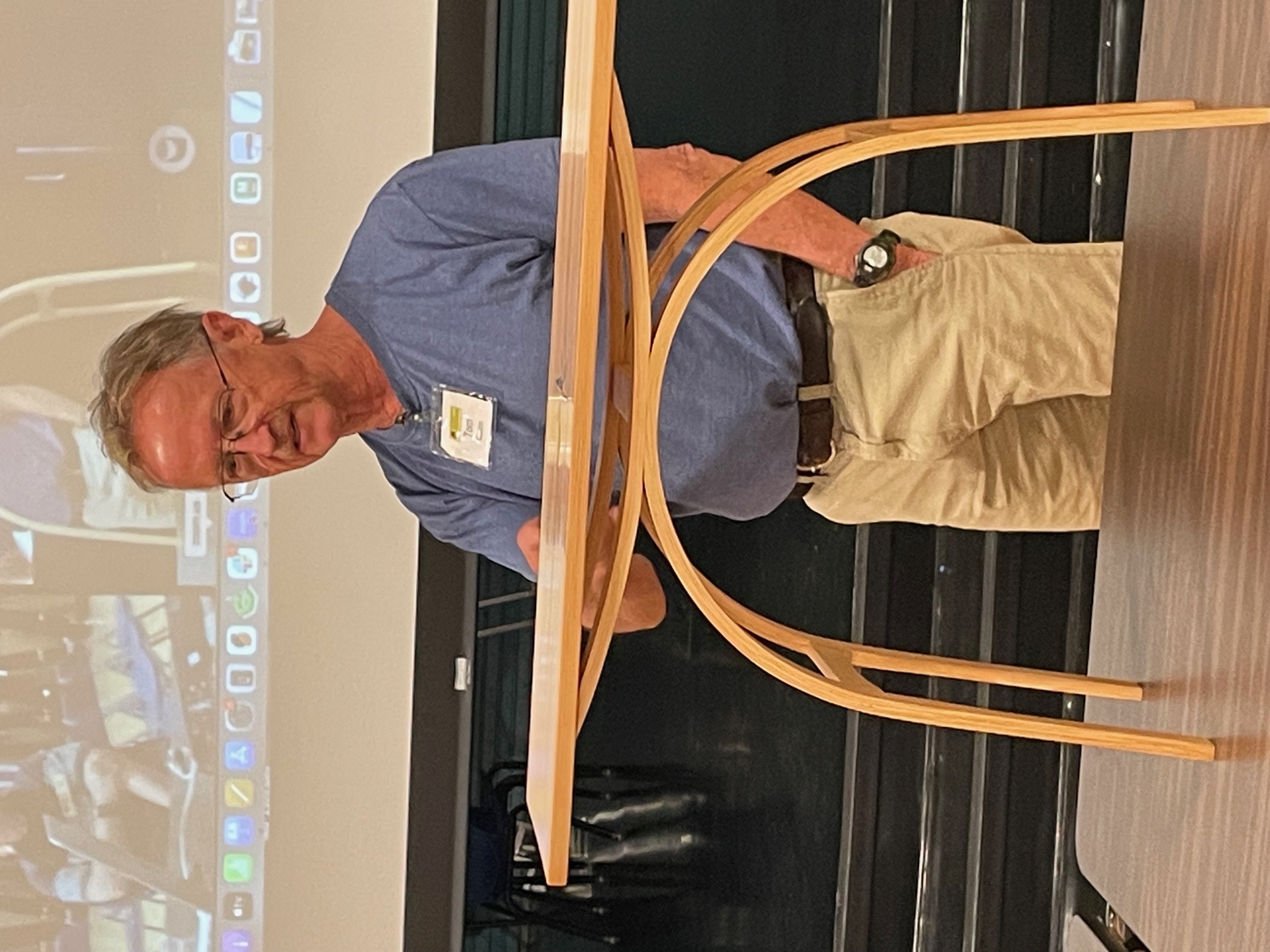

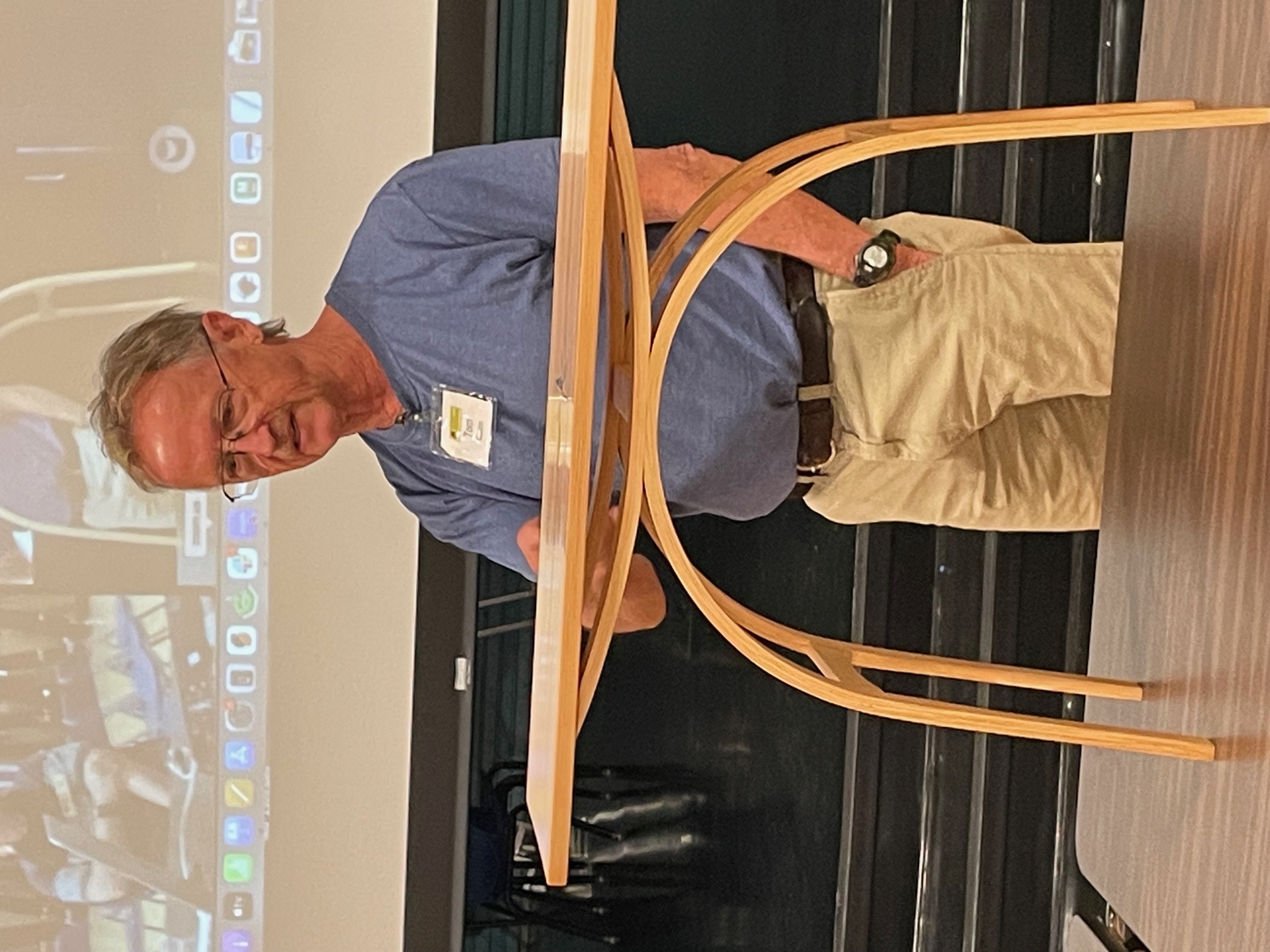

Tom Gaston brought in a decorative side table he made from laminated 2x4. It had arched legs and an arched support just above the legs that connected to the top. He said the laminated arched legs were glued with hide glue.

He said the hide glue will not creep like other glues will. The top has a marquetry star design that is made with bleached 2x4 and darkened 2x4.

Show and Tell

>>>>>>>>>>>>>>>>>>Need Picture>

>>>>>>>>>>>>>

Tom also brought in four turned bowls with grab handles built in.

Laura Rhodes

Laura showed slides of the marquetry topped box she made with hand tools. She even does resawing by hand.

Minutes by Burt Rosensweig

December: Ornament Challenge, Members bring in jigs and fixtures while we will have the Annual Holiday Party Potluck

Other announcements

Max Goldstein has a sturdy woodworking bench for sale. (please contact him directly: maxgoldstein1@gmail.com)

He also donated two back saws to the Palo Alto Adult School Woodshop.

Featured Speaker

Tonight's First Speaker: Lloyd Worthington-Levy

Lloyd described the process of making multiples of his Japanese Toolbox.

He bought an iGaging digital readout for his thickness planer that enabled him to dial in the exact thickness required wants.

(Editor's note: I have two of them on my desktop milling machine)

He cuts dovetails on his tablesaw using a sawblade with a 7 degree bevel on top to match the angle of the dovetail. (Available them from Forester for about $234)

Lloyd made 3D printed spacers/stop blocks for cutting the dovetails that way he could get repeatable distance between dovetails.

Knowing how important it is to assemble the box squarely, he made a fixture to hold the walls square during glue up.

The top is held in place with a wedge and opposing tapers using 3D printing

Lloyd made a jigs to hold the wedges at the correct angle on the table saw plus another one to position the wedges on the box top ane a final wedge is made longer than needed and trimmed to length after all other pieces are assembled.

Toolbox build: Newsletters/Newsletters2024/Pictures_October2024/Japanese Toolbox build compressed.pdf

Tonight's Second Speaker: Jamie Buxton

Jamie talked about the dining table he was commissioned to make for a client who had an 150lb. oval marble top but no base.

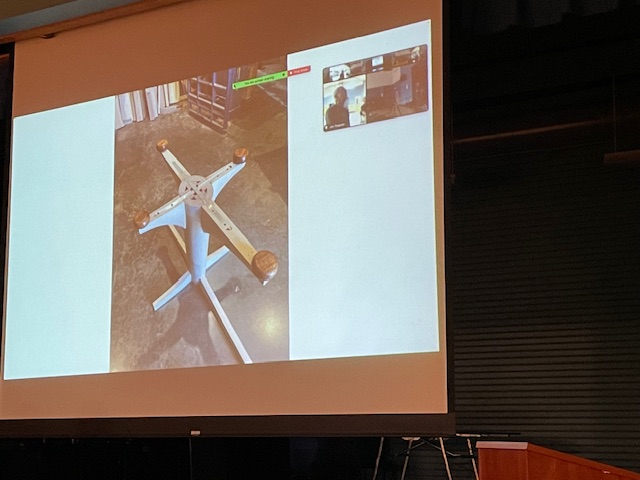

Base with supports

He made a wood base with Curly Maple on the outer edge of the oval below the marble top.

The central support post is made up of 8 pieces glued in an octagon. Each piece started out as 8/4 lumber. This tapered post was shaped into an oval using the jointer, the hand plane, and finally the random orbit sander.

He made stub tenons to attach the top support arms to the post and the same for the legs at the bottom of the post.

An angle grinder was used to rough shape the legs which have a half oval cross section. The leveling feet were made Khaya with 3/8in. threaded rod to attach the leveling feet to the bottom of the legs. 0.10 thick veneer was used to cover the outside edge of the wood that appears below the marble top.

Unfortunately the customer dropped and broke the marble top before the project was finished, so Jamie was tasked with creating a nice wood top to replace the marble.

Jamie bought Curly Maple boards and cut them to 0.10 inch thick so he could make a nice laminated top.

The Curly Maple vacuumed to a plywood base.

He made a MDF template to match the shape of the marble top base. The template was then used to cut the Curly Maple / plywood to shape.

It was also used to cut the Khaya surround to shape. He made two jigs to attach to his router to allow him to cut the inner and outer matching edges.

The finished table

The Curly Maple top is surrounded by a Khaya ring. He added a 3/16in. thick band between the Curly Maple and the Khaya outer. The base is protected with a sprayed on acrylic finish and the top is protected with wipe-on varnish. I am sure the customer will be happy with the finished product - it looks gorgeous.

2x4 Challenge

Max Goldstein

Max brought in a box with a hidden compartment. No one could figure out how to access the hidden compartment until he demonstrated the technique.

Laura Rhodes

Laura Rhodes brought in a box frame with four angled sides. She was trying to learn how to hand cut dovetails on a box with sides that are not vertical. She found it to be very difficult. She also wondered about hand cutting the groove for the box bottom, when the sides are not vertical.

Jon Kaplan

Jon brought in a 2x4 sculpture that was made up of very short pieces of 2x4 end glued. Laura said it looked like a DNA molecule.

Tom Gaston

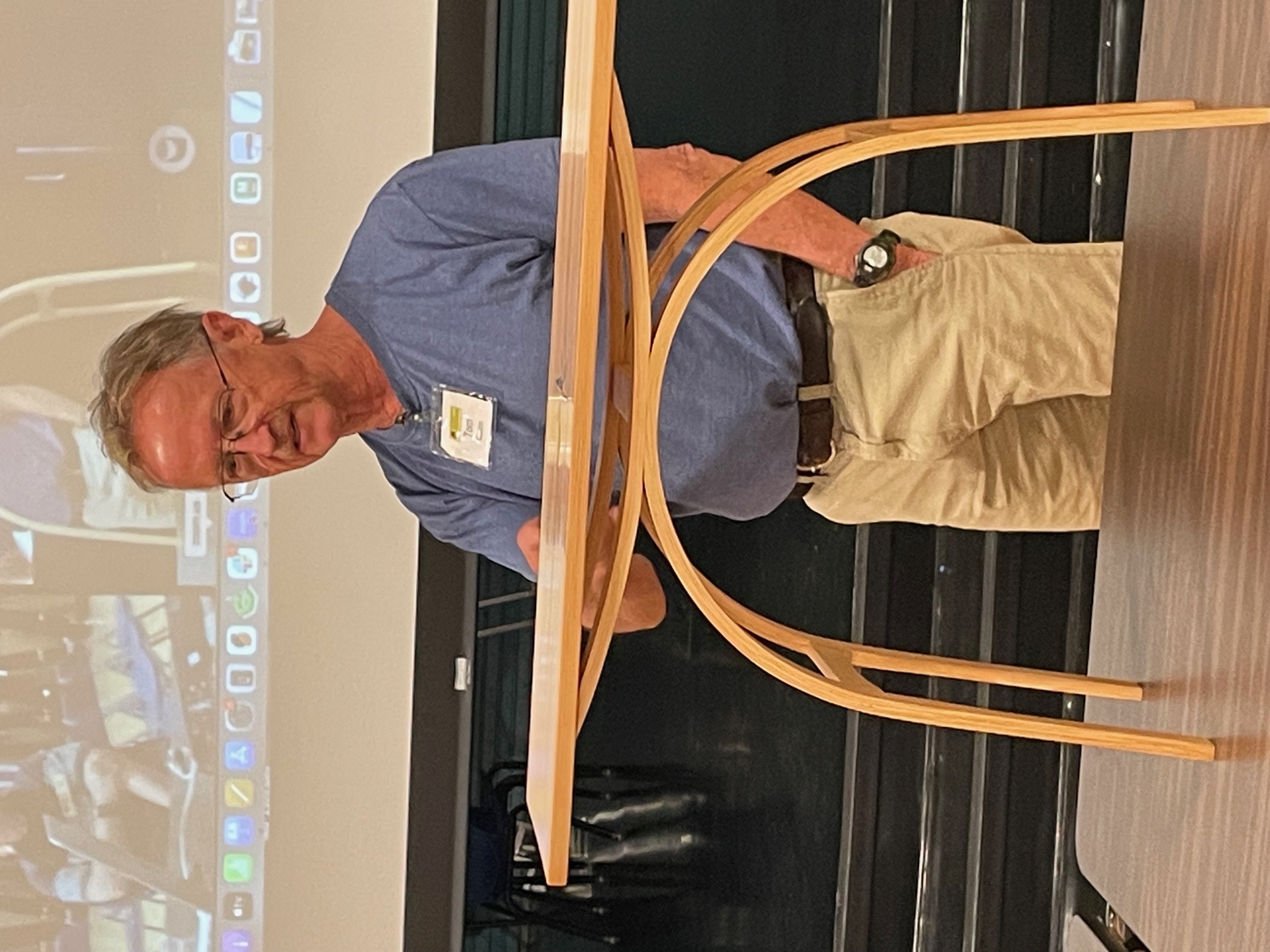

Tom Gaston brought in a decorative side table he made from laminated 2x4. It had arched legs and an arched support just above the legs that connected to the top. He said the laminated arched legs were glued with hide glue.

He said the hide glue will not creep like other glues will. The top has a marquetry star design that is made with bleached 2x4 and darkened 2x4.

Show and Tell

>>>>>>>>>>>>>>>>>>Need Picture>

>>>>>>>>>>>>>

Tom also brought in four turned bowls with grab handles built in.

Laura Rhodes

Laura showed slides of the marquetry topped box she made with hand tools. She even does resawing by hand.

Minutes by Burt Rosensweig

Tonight's First Speaker: Lloyd Worthington-Levy

Lloyd described the process of making multiples of his Japanese Toolbox.

He bought an iGaging digital readout for his thickness planer that enabled him to dial in the exact thickness required wants.

(Editor's note: I have two of them on my desktop milling machine)

He cuts dovetails on his tablesaw using a sawblade with a 7 degree bevel on top to match the angle of the dovetail. (Available them from Forester for about $234)

Lloyd made 3D printed spacers/stop blocks for cutting the dovetails that way he could get repeatable distance between dovetails.

Knowing how important it is to assemble the box squarely, he made a fixture to hold the walls square during glue up.

The top is held in place with a wedge and opposing tapers using 3D printing

Lloyd made a jigs to hold the wedges at the correct angle on the table saw plus another one to position the wedges on the box top ane a final wedge is made longer than needed and trimmed to length after all other pieces are assembled.

Toolbox build: Newsletters/Newsletters2024/Pictures_October2024/Japanese Toolbox build compressed.pdf

Tonight's Second Speaker: Jamie Buxton

Jamie talked about the dining table he was commissioned to make for a client who had an 150lb. oval marble top but no base.

Base with supports

He made a wood base with Curly Maple on the outer edge of the oval below the marble top.

The central support post is made up of 8 pieces glued in an octagon. Each piece started out as 8/4 lumber. This tapered post was shaped into an oval using the jointer, the hand plane, and finally the random orbit sander.

He made stub tenons to attach the top support arms to the post and the same for the legs at the bottom of the post.

An angle grinder was used to rough shape the legs which have a half oval cross section. The leveling feet were made Khaya with 3/8in. threaded rod to attach the leveling feet to the bottom of the legs. 0.10 thick veneer was used to cover the outside edge of the wood that appears below the marble top.

Unfortunately the customer dropped and broke the marble top before the project was finished, so Jamie was tasked with creating a nice wood top to replace the marble.

Jamie bought Curly Maple boards and cut them to 0.10 inch thick so he could make a nice laminated top.

The Curly Maple vacuumed to a plywood base.

He made a MDF template to match the shape of the marble top base. The template was then used to cut the Curly Maple / plywood to shape.

It was also used to cut the Khaya surround to shape. He made two jigs to attach to his router to allow him to cut the inner and outer matching edges.

The finished table

The Curly Maple top is surrounded by a Khaya ring. He added a 3/16in. thick band between the Curly Maple and the Khaya outer. The base is protected with a sprayed on acrylic finish and the top is protected with wipe-on varnish. I am sure the customer will be happy with the finished product - it looks gorgeous.

2x4 Challenge

Max Goldstein

Max brought in a box with a hidden compartment. No one could figure out how to access the hidden compartment until he demonstrated the technique.

2x4 Challenge

Max Goldstein

Max brought in a box with a hidden compartment. No one could figure out how to access the hidden compartment until he demonstrated the technique.

Laura Rhodes

Laura Rhodes brought in a box frame with four angled sides. She was trying to learn how to hand cut dovetails on a box with sides that are not vertical. She found it to be very difficult. She also wondered about hand cutting the groove for the box bottom, when the sides are not vertical.

Jon Kaplan

Jon brought in a 2x4 sculpture that was made up of very short pieces of 2x4 end glued. Laura said it looked like a DNA molecule.

Tom Gaston

Tom Gaston brought in a decorative side table he made from laminated 2x4. It had arched legs and an arched support just above the legs that connected to the top. He said the laminated arched legs were glued with hide glue.

He said the hide glue will not creep like other glues will. The top has a marquetry star design that is made with bleached 2x4 and darkened 2x4.

Show and Tell

>>>>>>>>>>>>>>>>>>Need Picture>

>>>>>>>>>>>>>Tom also brought in four turned bowls with grab handles built in.

Laura Rhodes

Laura showed slides of the marquetry topped box she made with hand tools. She even does resawing by hand.

Minutes by Burt Rosensweig