Newsletter May 2024

BAWA Hybrid Zoom Meeting May 19th 2024

The meeting was called to order by Frank Ramsay.

Program Announcements – Paul Krenitsky

June meeting: Box Challenge

October meeting: 2x4 Challenge

December meeting: Ornament Challenge

September meeting will be our Annual Members Picnic

We have a good number of members attending the Moore Newton visit Friday May 24th. and are getting together for lunch afterward.

Jon mentioned that we should consider car pooling to the event.

Laura emphasized that the BAWA Exhibition is coming up in 3 weeks and that while the show is in good shape we still need entries and volunteers. She passed around a sign-up sheet for volunteer positions for the show coming up in June.

Frank brought in a vintage BAWA apron for the Silent Action.

Stan brought in a woodworking vise and a number of woodworking books that he hoped to sell.

Featured Speaker

Jack West of Eggtooth Originals

Paul Krenitsky introduced our speaker via Zoom, Jack West of Eggtooth Originals (eggtoothoriginals.com)

Jack and his wife live in the Klamath Mountains. He retired from the Forest Service after 30 years. He built all the cabinets and vanities in his house, and made his own moldings.

He read James Krenov books and attended the Inside Passage school in British Columbia.

He built a workshop over a span of 3 years that houses his woodworking and his wife's jewelry making.

Mini Trillium Tale w/Slat Shelf

Walnut Winewave Rack

Side Table with live edge, Elm

Trillium table Spalted Maple drawer open

He would buy interesting looking slabs without having a project in mind, figuring that he would eventually use them.

He would make a mockup and then build multiples, often 4 pieces to sell.

From 2010 to 2023 he estimates that he has sold 150 pieces.

He would build what he liked and sell them at shows throughout the West. Jack made very few commission pieces.

He builds mostly tables. He started making live tenons for the joinery, but found that loose tenons were just as strong and quicker to make.

He uses metal clips to hold the table tops to the bases.

Jack mentioned that selling at shows was quite a gamble. At some shows he could make $5000, while at others he might not sell anything.

Recently Jack sold his planer and is selling more power tools while scaling back his operations. He tells us that we should seek out the finest

shows if we intend to sell high end woodworking.

He mentioned Kings Mountain as one of the finer shows in the area.

Jack's wine racks have 4 identical wavy vertical pieces that are laminated one at a time.

Dowel joints are used to attach the horizontal rails to the vertical pieces.

Show and Tell

Burt Rosensweig

The Ship Stand with his Ship Model

Burt brought his Ship Stand .The stand is made from Oak and Birdseye Maple from Frank's workshop lumber collection

Mortise and tenon joints are used.

The Oak is stained with Minwax stain and the Maple is natural.

Finish is Minwax wipe-on poly.

Dominique Charmot

Bruce Powell Showed photos of Dominique's massive curved front file cabinet made from Acacia.

Interior of cabinet with push-to-open draw hardware

Close fitting drawers

Dominique's notes:

I bought this slab of acacia at Global Wood Source in Campbell CA and produced just enough of 1/8th inch veneer for the project.

I built the frame out of Sapele for the front panel, plywood and Poplar for the side panels.

I then veneered all the panels with the Acacia in a vacuum press.

I then proceeded to cut out the openings for drawers and doors.

the construction of the drawers is straightforward, with the exception of the front, made of wiggle plywood sandwiched with Sapele 1/8th inch veneer and

formed in a vacuum press. The Acacia veneer is glued last (but first a label is inserted in the Acacia veneer by marquetry, yes because this is

still a filing cabinet!)

The drawers were assembled by lap joints.

Since I wanted to avoid anything that would interfere with the intrinsic esthetic of acacia, I went for push-to-open latches (hence no handles).

Finished with two coats of Osmo Polyx hard wax oil.

Dominique Charmot, Napa CA

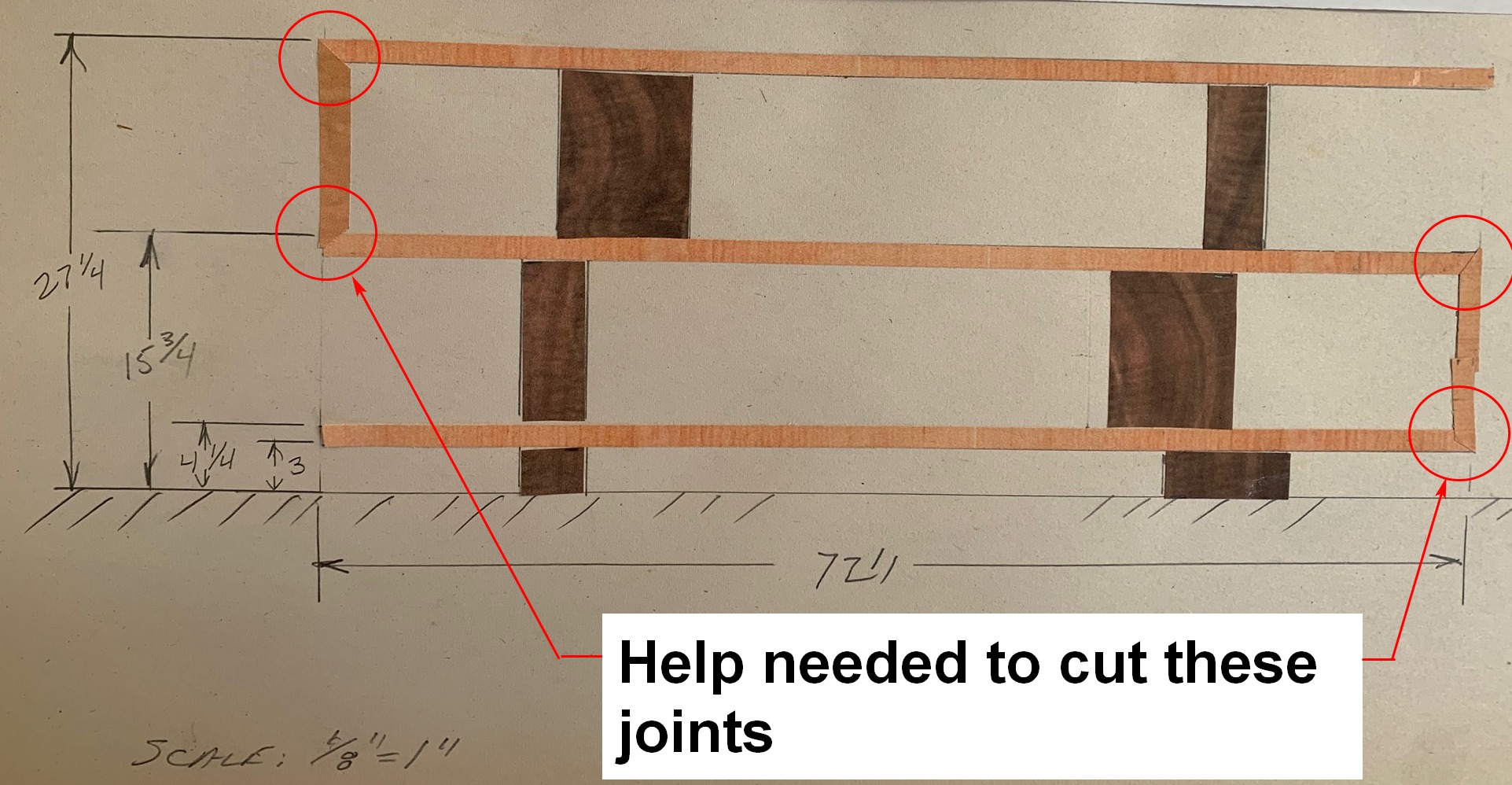

Bruce Powell

Bruce then showed photos of the Display Console he made for a commission job.

Original request

Dennis using his Festool

He thanked Dennis Yamamoto for offering to use his sliding table saw for cutting the miters on the ends of the 6 foot long boards and for

employing his Festool Domino machine to inset dominos to secure the joints.

Dave Burkett

Dave brought in a corn hole board he made. The top surface has Padauk, Maple and Cherry laminated to a plywood base.

Jon Kaplan

Jon showed a photo of the indoor planter box he made. This time it had parsley growing in it.

Lloyd Worthington-Levy

Lloyd in another of his Japanese toolbox style boxes he made. One had a marquetry top.

He noted that all pieces must be carefully aligned in order to avoid having gaps show on the top.

The Oak is stained with Minwax stain and the Maple is natural.

Finish is Minwax wipe-on poly.

Original request

Dennis using his Festool

He thanked Dennis Yamamoto for offering to use his sliding table saw for cutting the miters on the ends of the 6 foot long boards and for employing his Festool Domino machine to inset dominos to secure the joints.

Dave Burkett

Dave brought in a corn hole board he made. The top surface has Padauk, Maple and Cherry laminated to a plywood base.

Jon Kaplan

Jon showed a photo of the indoor planter box he made. This time it had parsley growing in it.

Lloyd Worthington-Levy