Presidents Message

Fellow Members :

Over the last few years I have heard members enquiring about having a BAWA show. An event where we can showcase our work to other woodworkers and the general public. It always seemed to be a good idea but we were never able to solve the logistics of where to have it and how to justify the cost. We needed a location with a good sized space and somewhere where we could expect to get many visitors passing through.

So now at last we are having the 1st Annual BAWA Show at Woodcraft in San Carlos on 11 and 12 December. Woodcarft have moved to their new San Carlos location. It is very a large showroom with floor to ceiling windows looking down on El Camino Real. They have been kind enough to invite us to use their showroom for our show. It will be a great occasion.

So now it is up to you. To make the show a success we need have a many exhibits. Furniture, boxes, turnings, jigs etc. Anything you have made and want to put on display.

We plan to make the show look special. All exhibits will be displayed on some form of dais or stand and will be distributed amongst the power tools etc that Woodcraft have on display.

In addition we plan to make it a party event. On the Friday evening between 6.00 pm and 8.00 pm we will have an opening reception where all of our members are invited to bring their partners or families for a great social evening.

You will be getting a email in the next week with all the details.

We also have a new look website where we would like to increase the visibility of our Galleries. This is where any member will be able to have their works displayed along with a brief description. Another opportunity to showcase your work. I hope in the next few months we add a link to allow people to provide you with comments on work in the Gallery. So we are soliciting pictures of work you would like to have in the Gallery. Just send them to me, electronically preferred, along with a brief description and they will be added to the web.

I look forward to seeing you all at the Show in December.

Frank R Ramsay

President

frankramsay8@aol.com

Frank Ramsay called the meeting to order shortly after 7:00 pm, noticing that we had several guests in attendance.

Guests

Jim Bellison , Bob Grosch, who lives in Redding and was a guest of Stan Booker

Dave Tucker, who was a member 10 years ago and has come back to the fold.

Dean Sinisgalli

Announcements

Mark Rand announced that the next meeting has two events: the Box Contest and Jigs and Fixtures Show

Stan Booker announced that the zebra wood raffle prize would be awarded tonight. John Blackmore later proved to be the lucky winner. Stan has many other valuable door prizes. Come to the meeting and you too can win.

Stan Booker also read a thank you letter from the Director of an Apprenticeship School in Tanzania thanking BAWA members for their donations of books and tools. All donations, including old computers are welcome.

Per Madsen reviewed the upcoming meetings that are described elsewhere. A special Saturday Sketch Up class is scheduled for November 20. The cost is a nominal $20. It will be held at the William Walker Recreation center in Foster City.

During the November meeting BAWA will hold its annual election of officers and hear the Treasurer's Report.

Harold Patterson in holding a Toy Workshop on October 30 at Jamie Buxton's shop in San Carlos. It starts at 10 am and runs until 4 pm. Frank Taylor is coordinating the wheel making efforts. Contact him if you can help out.

Steve Rosenblum described the planning that has gone on for the Woodworking Show that will be held the weekend of December 10-12. The exhibition will be held at the new Woodcraft store in San Carlos, courtesy of Eric McCrystal. A sign up sheet was circulated and already we have 8 exhibitors. If you are interested, let us know right away. It will be a non-juried event. The fee is $20 for up to two display items. Additional items will cost $10 each. Items will be displayed on stands provided by each exhibitor, then draped with a white cloth. Friday night there will be a reception for exhibitors and their guests. The cost to attend this event is $5 per person and the cost includes hors d'oeuvres, wine, and a raffle prize. Each item displayed will have a standardized descriptive label and be accompanied by a short biography of the craftsman in a seperate separate binder. Postcard flyers for the show are being prepared. This show is a great opportunity to exhibit your work. Furniture, boxes, jigs, fixtures, and photography are all welcome.

Woodcraft Dublin & Woodcraft San Carlos give the club a rebate on all purchases. Give receipts to Mark Rand.

Show and Tell

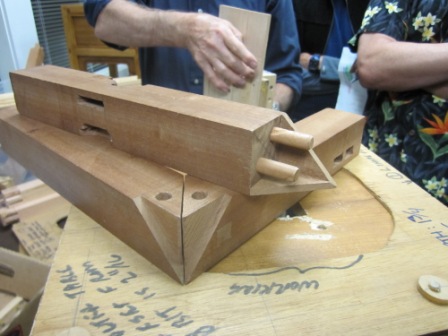

Bruce Powell gave a short presentation on Chinese joinery, showing fixtures he made to create the joints. As an example of the joints, he showed a small Chinese style table and photographs of a Round Corner Cabinet with legs splayed out from vertical by 1 degree, nine minutes. The table had a three-way miter joint with joints cut on a jig with 6 templates for making progressive router passes.

Frank Ramsay showed the prototype he constructed before making a finished Japanese three-panel screen. The final screen was made with mahogany, beech and mulberry paper. The hinges open in two directions. The screen uses 3/8" lap joints.

Frank also showed us the fired off SawStop cartridge and damaged Freud blade resulting from a miscut on his table saw. Don't cut into your miter fence.

Frank has made a cabinet with Chinese joinery. Not only were the joints complicated, but the cabinet sides angled two degrees towards the center. Frank could just not visualize how these joints would go together, so he turned to SketchUp to show the geometry. First he created a cabinet with vertical sides, and secondly he modified it to include the angled sides. We impressed. It all seemed so simple and straightforward. Now the SketchUp class sized has zoomed up beyond the manageable. You have created a conundrum for yourself, Frank.

John Blackmore brought in the small "Sow's Ear" wall cabinet he started while attending the Tools and Techniques class at the College of the Redwoods this past summer. It is made from a single 2" x 12" x 24" block of poplar, that was cut up and divided into all the component parts. John said this class was the best three week long vacation he has ever had.

Jay Perrine, George Bosworth and Claude Godcharles

Setting Up Your Garage Woodworking Shop

Jay Perrine introduced the three presenters: himself, George Bosworth and Claude Godcharles

Jay encouraged us to consider some things before starting to plan the new shop layout:

·How will the shop be used?

·What are you going to build?

·Where will you put your lumber and scraps?

·Establish the location for all your tools.

·Think about working conditions, including heat and light.

·What are the electrical requirements?

·Be imaginative when considering where to store everything.

·Anticipate making changes, because you will rearrange your shop each time you buy a new tool. Think about jigs, fixtures, sheet goods and workflow.

Then Jay turned the gavel over to George Bosworth who had obviously done some serious planning to put together his shop. George lives in a condominium and he converted a second story bedroom, right off the dining room into his workshop. It measures 9 feet by 11 feet, nine inches with an 8 foot high ceiling. On one wall he has a 4 shelf unit, holding plastic storage boxes, carefully arranged three high on each shelf. He pulls out one, and the ones above simply slide down. To protect the shelves from dust, he has mounted a pull down roller blind to the ceiling just in front of it. All the machines are on wheels, including the DeWalt table saw. He converts the table saw to a worktable by placing a hard board top on it. He has a power tool tower in the room measuring roughly 3 x 3 x 8 feet with three shelves. He keeps the planer on one shelf, the drill press on another and the cross-cut saw on a third shelf. He has devised a block and tackle system that slides along a ceiling mounted round 1 1/4 in pipe, filled with a wooden dowels for rigidity, to retrieve a tool as needed from the shelf that he then places on his work table. He can remove or replace a tool from the tower in about 1 1/2 minutes. He has additional storage in his garage and keeps infrequently used tools in a bedroom closet. When he needs sheet goods, he gives the cutting dimensions to the woodshop where he buys his wood. Then, he does not have to concern himself with large and long pieces of wood.And it all works. Great planning and implementation, George.

Claude Godcharles used a different philosophy when putting his 20 x 20 foot garage woodworking shop. Claude is a fortuitous scavenger. It seems that whenever he needs cabinets, shelving or other items for organizing his shop, he just happens to come across them on the street with a "free" sign attached. True, he has had to repaint some of the cabinet. Just look at the nice yellow and red paint scheme on his all-purpose bench with drawers. He even added a narrow small tool storage tray on the front just below the top. That way everything is within reach. And Claude is a collector. He collects wood boards, tree rounds for turning, and tool deals. Just look at that Rockwell hardness tester he picked up for $20 at an estate sale. It goes for $1,000 on eBay. He has wood behind his garage, on the side of the house where his wife never goes, and some temporarily stacked on his front porch. With the double garage door up, we saw a picture of a shop crammed with tools, storage, and wood. Carol Reiser was moved to inquire where Claude's wife gets to pack her car. Claude had diagrammed the garage layout for us so that we could locate everything in the photographs. Claude has a single line dust collection duct along one wall. Everything connects to it via flexible plastic ducting. The lathe is fixed in location just in front of the dust line. He has added pull out drawers just below the lathe to house all associated tools and fixtures. All the woodworking machines are 110V although Claude is planning an upgrade some to 220V, but that will require some electrical panel changes. He has installed T8 fluorescent fixtures with electronic ballasts for better lighting and less noise. Storage is an important consideration for Claude. He has built a "cleaner" area in one corner of the shop with plywood walls. Then, he can easily hang things from this stronger wall. Above this area he has wood storage racks. The guide rails of the garage door were used to support high storage shelves on either side of the garage door. Above the garage door itself, Claude has installed two inverted "T" racks to hold even more lumber. And, Claude supports the notion that you change and improve the shop layout with each additional tool purchase. His next improvement will be to move the dust collection system to an as yet un-constructed outside shed. He also has plans to add a power feeder to his router/shaper.

Summing up for his panel, Jay advised us all to plan for change, look at your workflow and forget about parking the car in the garage. We adjourned and lugged off our prizes.

John Blackmore

No This and That this month

Classified ads must be from members or ex-members or their estates who are closing down their workshops. In addition a non-member may attend a regular meeting as a guest and announce personal items for sale that are directly related to member's woodworking. The details of the announcement may be covered in the meeting minutes in the monthly newsletter, subject to editorial review.

Do you have something to sell or trade? Let me know by the last weekend of the month and I'll put it into the next newsletter. Let me know if your item sells so I can delete the ad.

Steve Rosenblum

650-322-9560

212 Santa Rita Ave

Palo Alto 94301

steve@rosenblums.us

For Sale (9/10)

Rojek MSP 415 jointer/planer, 16?, single phase, 230V, 60Hz, mobile base, horizontal mortiser, new motor. $3400. johnblackmore@comcast.net

For Sale (9/10)

Honduran mahogany lumber, various sizes, 15% discount to lowest Bay Area price. Lum40@comcast.net

Wanted

Use of a drum sander to finish sand a 24 1/4 x 49 x 1 1/2 inch counter top, fee negotiable, call Steve Rosenblum, 650-322-9560