President's corner

![]()

Fellow Members

We have a lot of good wood in America.

I was recently in Taiwan and saw several of the impressive grand lobbies and public rooms in hotels such as the Weston etc. Magnificent architecture incorporating lots of real wood everywhere. Later I was very fortunate to be able to meet the creator of all of this woodwork. A gentleman who left school at 14 then worked in the local gold and coal mines before deciding to become a woodworker. Today he designs and makes the woodwork for many of the up market hotels all over in Taiwan.

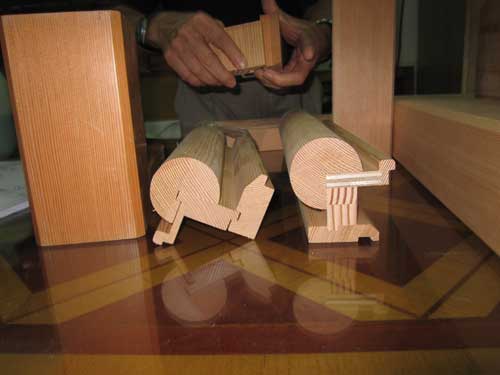

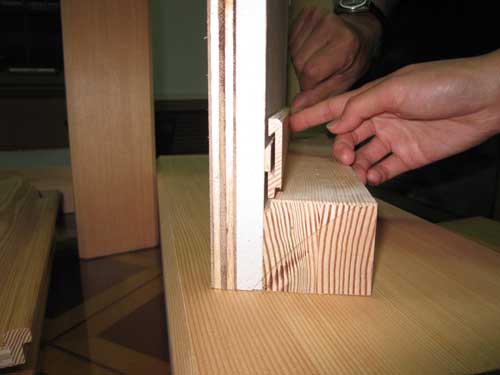

He has a factory in the small town near where he was brought up. There is no computer design or CCM work involved, not even engineering drawings! He sketches the designs for the cross sections of the framing etc. on bits of paper then makes a full size sample, has the architect sign off on it then manufactures it in his factory. He also makes custom chairs and other furniture for the hotels, sometimes production runs of a few hundred at a time.

He took me to visit his factory and showed me samples of some of his work. That so many impressive wooden interiors could be manufactured in a factory with just had a few older type large saws, molders and shapers etc was amazing.

The other surprising thing was that most of his interiors were made from imported American Fir. The straight grain was easy to work with and suitable for staining to uniform finish of some kind. He also imports 1/8 inch thick straight grained Fir veneer to cover the plywood paneling from America.

Closer to home BAWA had a visit to California Urban Lumber in Martinez recently. www.calurbanlumber.com/

They have several big milling machines etc for converting tree trunks into lumber and then into architectural lumber. They are a green company, which means they only use trees that have been felled "by necessity" ie: natural mortality, city ordnance etc. They work with a wide range of local woods including Redwood, Walnut, Oak, Monterey Cypress and Eucalyptus. Most of their logs come from within a 20 mile radius of their facility. Yet even with their self imposed "green" conditions they are currently able to find enough trees to mill the lumber for a 6500 sq ft house being built in the area. The house will have Redwood sidings and a Cypress paneled interior. The project also needs about 100 doors that they have to manufacture, some at 4 inch thick. These to will be made with local green wood.

By coincidence in the San Francisco Chronicle on October 18th there was article about the Eucalyptus trees that have been cut down in preparation for the roadwork on Doyle Drive. www.sfgate.com/cgi-bin/article.cgi?f=/c/a/2009/10/18/HO9G19SN9T.DTL

They are now at the Green Waste Recycle Yard, another green lumber yard. www.greenwasterecycleyard.com/

The article has a picture showing an office building they built with recycled Eucalyptus.

The world is using a lot of American wood, most of it sustainable or recycled and a lot of it found locally.

Our natural resources are impressive.

Frank Ramsay

Frankramsay8@aol.com or 408-823-2382