Last meeting

![]()

President Craig started off the meeting with a thank you to Tony and Robbie Fanning, Fred Reicher, Arnie Champagne and others for the help in making the September Fall Kick Off meeting a huge success.

He also mentioned that John Schmidt will be having an Open Shop at 10 AM on Saturday November 19, 2005 in Oakdale. In addition after lunch, there will be a visit to the shop of Johnny Jones. Both have really great shops. Craig thinks that possibly members can carpool as was done last year when a good sized delegation when to visit.

Our Rafflemeister, Stan Booker then described the evening's door prizes: two turning blocks, a set of clamps and Gorilla glue. A very large board of Paduak with an interesting pattern is available for the raffle. Tickets are $1 each or 6 for $5. Not enough tickets were sold at the meeting so it will continue at the November meeting.

Tony Fanning announced that small wood objects are needed for the locked display case at the Woodworking Show. He was also looking for volunteers "to do an Arnie" at the show; that is, to demonstrate woodworking techniques. Dick Reiser will turn pens for the "Turning for the Troops" on a lathe borrowed from Woodcraft-San Carlos.

There will be a Chair Display at the Woodworking Show. Chairs will come from Eric McCrystal, Dan Goodman and Jamie Buxton. Tony will also have a display board showing the steps to make a chair. However, you can't try and make a chair right there in the aisle at the show.

Eric McCrystal described several specials at the Woodcraft Store. The Bessy clamp sale was a huge success and he expects to run it again in December with another 600 clamps. The discount is 40%. The store's first anniversary is coming up November 5 & 6 and there will be a "pick your discount" sale. There will be a pen turning event called "Turning for the Troops" on November 11 & 12. The goal is to finish 600 pens. The store has the new box chisel sets from Lie Nielsen. He also said that the space BAWA has been using for its meeting can continue to be used until a lease tenant is found.

Harold Patterson is scheduling a Toy Workshop for November 20 at Woodcraft in San Carlos, from 10am to 4pm. The workshop participants will build crickets and race cars. Contact Harold at haroldp@comcast.net or 650/349-7922 if you would like to attend. Harold also had copies of the membership roster and the Restoring Planes instruction sheet.

Show and Tell was next.

Claude Godcharles made a low 3-leg Mesquite stool, and a higher 6-leg Beech stool salvaged from a discarded table. The table legs showed turned ends of graduated length. The stool top had handles with a laminated walnut overlay, pattern drilled with a core box bit. He showed us some carpenter bees he captured once they escaped from a piece of wood he was machining. No, he did not have them on little leashes but in a jar of fluid. It was very unusual to have a lot of them in one board since they are usually solitary beings.

Gene Clark had made a Walnut box for his grand-daughter. The Walnut was one continuous strip. He book matched the Maple on top. The top is opened and inserted into groove slots at the back of the case to hold it open. There are no hinges. He finished the box with 6 coats of MiniWax, rubbed out to 600 grit.

Jamie Buxton showed pictures of a three case side-by-side chest of drawer set constructed of Red Oak with a design overlay of metallic copper foil. He filled the grain with two coats of Goop-on, then sized or varnished the pattern on to the wood. The metal foil was placed on the sizing, causing it to adhere firmly. The excess was simply washed off with alcohol. The finish coat was two applications of water based spray varnish. With encouragement from the membership, Jamie agreed to a Tech Talk demonstration in January.

Obie Gilkerson showed two turned bowls. The first bowl was made out of an elegant piece of Walnut salvaged from a backyard tree. The second bowl was turned from a Camphor burl using a Stewart tool with a laser beam which shows the thickness of the wall. He designed the laser arrangement himself. The bowl was only ¼" thick. He used 6 coats of Liberon finishing oil.

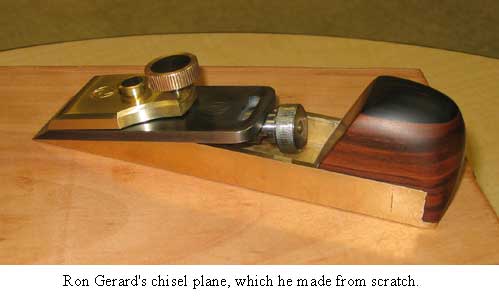

Ron Gerard showed a chisel plane he had made from scratch. The base is brass, the handle made from Plum. The blade is honed to 25 degrees, the blade set at 12½ degrees. Ron Hawk heat treated the blade for a mere $5.

Arnold Champagne announced that he is going on sabbatical for the next six months and will not be offering classes. He is too busy and wants a rest.

David Klinke is moving to West Virginia to accept a professorship. He has several tools for sale: an 8" Grizzly jointer, a Jet table saw and some Poplar and Maple.

Fred Reicher has a friend who would like to give away a 10" Craftsman radial arm saw.

Craig then invited guests to stand up and identify themselves. Dennis Stewart and Ralph Northrup both found us on the web. Zack Deretsky is a woodworker friend of Jamie Buxton. A warm welcome was given to all.

Following the break with its frenzy of buying at the Woodcraft store, Craig introduced our Featured Speaker, John R. Shelly, PhD. John is the Cooperative Extension Advisor -- Forest Products and Biomass at the University of California, Richmond Field Station. John received his BS degree from Penn State and his MS and PhD degrees from the University of California, Berkeley. He is the Cooperative Extension Advisor in Biomass and Forest Products Utilization. His primary interests and expertise are in the physical properties of wood and manufacturing technology with an emphasis on biomass, that is getting value from under utilized wood and wood by-products, including urban timber species. He is an expert in the utilization potential of western hardwoods species infected with Sudden Oak Death tree disease. Yes, the wood can be used with low risk of spreading the disease.

John could talk for hours on many subjects but decided to limit his presentation to Why Kiln Dry Wood and Wood Pests. Why dry wood? Wood is dried to reach a target equilibrium moisture content (EMC), to minimize dimensional changes, to control insects and to prepare the surface of the wood for finish application.

The equilibrium moisture content of wood can vary by geographic region in California. Typically, the coastal areas have EMC of 10%, inland areas 7-8% while the desert and high mountain areas have levels of 7%.

If you are going to build furniture it is wise to know where your target audience lives and will be using the furniture you make. Hardwood floor manufacturers typically dry their flooring to a moisture content of 6%. Therefore, installers will always allow the wood to acclimate on site for at least 2 weeks. It should be stickered for good air flow. In California Tan Oak and Madrone make excellent flooring.

Kiln drying under controlled conditions accomplishes several things: It minimizes wood shrinkage, controls checking, can eliminate insects and sets the pitch in the wood. Insects are killed when wood core temperatures reach 140 degree F. The volatile gases in the pitch are cooked off at temperatures above 170 degrees F.

There are several drying defects to be aware of when selecting wood. Growth related defects include warping. Stress related defects include checks, honeycomb, collapse and case hardening. Discoloration can occur from decay, a biological phenomenon, from chemical oxidation of the enzymes, mineral streaks and sticker stain.

The rule of thumb for wood movement is that tangential movement with the grain is twice that of radial or against the grain movement. Therefore, shrinkage depends very much on where the board is cut from the log. Quarter sawn wood is the most stable.

Most defects occur when the wood is dried too rapidly resulting in irreparable damage to the wood. We saw several examples. Collapse results in misshapen, out of dimension lumber. Honeycombing is evidenced by clefts in the wood. Case hardening causes the surfaces of the wood to harden and can sometimes be corrected with steam.

Dr. Shelly explained the cellular structure of wood, differentiating between the soft and hard woods. The latter are more complex, representing a further evolutionary development of the wood structure.

Generally, in the wood we see rings or late growth wood that is denser than the intervening early growth and softer wood. Interspersed across the grain are rays.

Wood dries from the outside to the inside. Effective drying requires that the temperature gradients across the zones from the outside to the core be watched carefully. If the gradients are too high, the rays will collapse and wood defects result.

And Then Came the Pests

John categorized the pests as Termites, Carpenter Bees, Beetles in wet wood: Round headed, Flat headed and Ambrosia. In dry wood: Powder Post: Lyctid, Anoibiid, False Powder Post: Bostriched. Termites are well known and Claude Godcharles has introduced us to the Carpenter Bee earlier in the evening. John Shelly focused on the beetles.

Generally the wet wood beetles are less of a problem to woodworkers than the dry wood beetles because they only infest wet wood. Therefore re-infestation does not occur. We saw a specimen of a large Ambrosia beetle 2" long and 3/4" in diameter. These wet wood beetles are larger than their dry wood cousins. The life cycle of both types is that the larvae are deposited in the wood, hatch and begin to eat. They eat until mature, they emerge from the wood, leaving a hole. They look for a mate and the cycle starts again.

The Powder Post beetle is especially troublesome. They love old Redwood wine vat wood and Madrone. John described a house in Oakland, reconstructed after the fire with vat Redwood. It became infested, resulting in a massive tearout and redo.

Another example was a house in Ukiah constructed with Madrone flooring. The flooring manufacturer had kiln dried the wood to only 120 degree F, had no insurance and the floors were gone in a year. We saw samples of the wood that had been removed.

In another case, a woodworker had made a fly fishing net using Madrone for the handle and frame. Unbeknownst to him, it was infested. A year later he was surprised to see the frame shatter when he accidentally dropped it on the floor. The frame fragment we saw had only a thin veneer of wood covering the frass, or sawdust tract of the beetle.

John recommends that infested boards not be used. However, single boards can be fumigated by licensed pest control companies. Timbor type products are becoming available, try McBeath Hardwoods.

John invited members to contact him with any questions that they may have at john.shelly@ucop.edu

The meeting ended with a bunch of lucky winners of the door prizes.

We then all rushed home to inspect our stockpiles of lumber, our house framing and put away our acquisitions from the store. Several gave Mark Rand their receipts which Woodcraft converts to a refund for the club. Thank you woodworkers.

John Blackmore & Mark Rand