Last meeting

![]()

There was a large group gathered at the December meeting. We had visitors and some new members as follows. Jack Oakley, Don Sherer, Vern Wassman, Neil Fredrickson, Bill Deihl, Bob McCowan, John Blackmore, Scott Bloomquist, Earl Beland, Ked Seidman, Tom Kochenderfer, Randy Fry, Russell Webber, Joseph Mejia and Joe Ng. Welcome to all and we hope you find our meetings enjoyable.

Tech Talk

Carl Johnson's Tech Talk on sharpening scrapers was back by popular demand, or as Carl put it, "Some folks couldn't remember what I said before so I will repeat it." Carl went through the steps orally, then sharpened one in front of us using a clever setup to fasten a vise to the table available in the conference room at Foster City. Then, Carl proceeded to use the sharpened scraper on a piece of wood and the thin shavings were passed around the room and brought a much-deserved round of applause. Finally, Carl passed out a 3-page handout describing what he had just told us and show us. This may reduce the amount of sandpaper purchased in the Bay Area for awhile as members employ this newly-learned or recently-updated skill.

Main Presentation: Jigs & Fixtures

Jigs and Fixtures made by our members were the evening's main presentation.

Stan Booker showed a fixture that goes on a disc sander. His students (11, 12, and 13 years old) use it to make miter cuts.

Arnie Champagne showed corner blocks made from scraps of Finn ply. They are useful in assembly of boxes and drawers.

Paul Reif showed three jigs. The first was a tablesaw cut-off box that makes very accurate miter cuts. The design is from Yeung Chan's recent book about joints. The second jig was for cutting mock dovetails or mock finger joints on a table saw or router table. The third was a router jig for mortising butt hinges into small boxes.

George Bosworth showed a spring board. It is an alternative to feather boards. He says it is better because it provides a more-constant pressure.

Neil White showed a router jig which he first claimed was a bullshit grinder, but then he admitted it was a device to cut ellipses with a router. He also showed a jig for a bandsaw fence that allows fine-tuning of the width cut by the saw.

Bill Mannix showed the most complex jig of the evening. It was a horizontal mortising machine. It uses a router to spin the bit, and calibrated threaded rods to set the depth and length of the mortise.

More photos can be seen here.

Bill Henzel showed a jig for making dowels. It uses a drill to spin the stock, and a router to cut the surface to the exact diameter.

Harold Patterson showed a tablesaw push block designed to be cut into. It gives tight control of the workpiece, particularly ones which are too small to safely hold with your fingers. When it gets too many cuts in it, the chowdered-up face gets replaced.

Reports

Treasurer's Report: Over $700 spent for the WW Show, including the display case which utilized donated money from a non-profit (and we are also a non-profit, by the way). There is currently about $1,500 in the bank, but only about $50 in the checking account since Gene Wagg, our faithful Treasurer, has moved the major amount of cash to a savings account for our benefit.

Outreach, Harold Patterson: Two Toy Workshops planned. Santa Claus himself might visit it was announced so everyone scurried to sign up. The next Workshop is planned to be at the workshop of Bill Henzel and Harold passed around a sign-up sheet for that. They were planning to make some rocking horses and Harold passed out templates and asked people to make parts (even if they were not able to stay for the workshop). A clever approach for the workshops since there are so many pieces to make. It was mentioned that this is not just for the underprivileged children but also for members to work together and get to know each other in a shop setting. It was mentioned that at Toy Workshops the table saw use is restricted to the shop owner to reduce risk to volunteers.

Membership: First it was announced (and repeated several times during the meeting) that this was The BEST EVER presence at a Wood Working Show. The signs helped (thanks Tony), the Display Case helped (many thanks to Craig, Don, Tony and Gene who spent like 3 week-ends on this project). All the steps and procedures were written down by Robbie Fanning and will be available to the new Chair of the Woodworking Shows.

Program Chair, Jay Perrine: Paul Reif, very familiar with Berkeley Mills the site of our December meeting added that this is almost a must see place since they have 8 separate work areas with the latest woodworking equipment. They have an entire line of furniture with an Eastern flavor.

Announcements, Q&A: 1. Tom Keller, a friend of Carl Johnson has a 3,000 sq. ft. workshop in Redwood City that he is interested in renting out in some manner. The reason is that he has suffered a stroke and it may be a year or more before he can get back to things. He would probably consider an offer if several woodworkers went in together to rent the facility. This would include the use of the tools in there. The concern is probably to get the rent paid and not be forced to undo the workshop. Contact Carl Johnson for further information. 2. Larry asked about the Ryobi sliding table saw. Three or 4 members mentioned that it is wiggly and not accurate. 3. Al Semenero, a prior club president relayed a story that he visited the Allied Arts workshop on the Peninsula. They have, among other things to visit at the facility, a barn with a complete old-time woodworking shop. Al passed on the material to our Program Chair as an idea for a future meeting. The woodworking shop is run by the grandson of the fellow who originally ran the shop in the early part of the previous century (the one during which most of us grew up!).

Show & Tell

Don Naples showed some samples of holy wood. This, it turned out, is not some new species of tree. Rather it is lumber salvaged from a church in Petaluma by several BAWA members. Don reported that it is great oak, but that it beat the heck out of his surface planer.

Arnie Champagne, who had also been part of the scavenge team, showed holy wood turned into components for a cabinetmakers bench.

Richard Winslow showed a walnut jewelry box with fine handcut dovetails. He also showed a Parson's table made by eighth graders he teaches once a week.

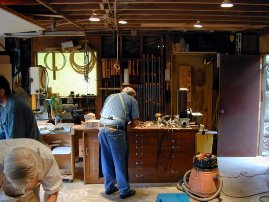

Toy Workshop

We had a toy workshop at Jamie Buxton's shop on Novenber 23. George Bosworth, Mike Bray, Per Madsen, Gene Wagg, Jay Perrine, Brent Tolosko and Harold Patterson machined 6 Xylophones out of recycled church oak. It was very interesting and educational setting up a production line. Many thanks to Jamie for loaning his shop and doing all the planing and cutting. Mike and Brent turned out to be drill press meisters. Mike and George did most of the layout and there were a few technical problems which were solved collectively. Per is welcome at any workshop, as he came prepared with pastry. Jay and Gene were the master sanders and assemblers. After the rest of us had been working for three hours, Tony Fanning showed up and took some pictures. We took this as our cue that it was time for lunch. We all carpooled to a Tex/Mex restuarant called Coyote's in the Carlmont Shopping Center in Belmont. The food was wonderful and after a leisurely luncheon we returned to Jamie's. The afternoon session was taken up by final base assembly and tone bar machining. A special jig was used to hold the round balls steady for drilling the hole to connect to the mallet handles. I plan to bring this jig for show and tell the next meeting. It was getting a bit late so we gave the last six people left, one xylophone kit to take home for final assembly. You will be able to see them at the meeting on the 12th.

More photos can be seen here.