Newsletter December 2020

President's Message

Fellow woodworkers,

Quoting from Her Majesty the Queens' Christmas Message from 1992:

… the year "it has turned out to be an annus horribilis"

We started the year with regular meetings in January and February then, as the dark clouds of the virus started to emerge, we made the decision to cancel our March meeting, just beating a local government's close down directive.

Mike Tracy and team had planned our Annual Woodworking Show for the end of May. Just before we cancelled our March meeting, I had picked up the postcards and posters for the show.

During March we posted several Show and Tells, then in April, started having Zoom meetings. The process was led by Bruce as many of us had not previously used Zoom. In July we started inviting Guest Virtual Speakers.

Our Zoom meetings became more popular than I had expected; it was good to see several ex-members from the East Coast plus others from the Bay Area join and participate.

At our February meeting Paul coordinated a workshop on card scrapers. By June Paul's presentations had morphed into Virtual Workshops Tours covering topics from Table Saws to Small Part Storage Systems; in the Workshop on Bandsaws the attendees presented 17 different Bandsaws.

During the year we also had over 50 Show and Tell presentations, an all time record. Members put extra effort into their presentations, often preparing a slide show rather than just showing their work.

Jon Kaplan had a monthly "Covid Woodworking or Keeping busy with Little Pieces of Wood" update which include his warm-up practice of cutting several sets of hand-cut dovetails every time he goes into his shop.

The range of Virtual Guest Speakers we have had included furniture designers/makers, a talk on the Shaker Legacy and a presentation from the Maloof Foundation.

We need to continue to have virtual meetings for several months but I am looking forward to seeing you all at our first in-person meeting when it happens; we may even turn it into a party.

It was a different year, but there was lots of good woodworking information, knowledge and ideas.

I wish you all a very safe and happy holiday season

Look forward to seeing you in 2021.

Frank

(Contact at:

Frankramsay8@aol.com)

Top

December 2020 BAWA Zoom Meeting

The meeting was called to order by President Frank Ramsay.

Announcements:

Treasurer Jon Kaplan announced that we have 15 members renewed their membership for 2021 so far.

2021 membership dues are $48 and should be sent to him by check.

Address

BAWA

c/o Jon Kaplan

682 Georgia Ave.,

Palo Alto,

CA 94306

We are assuming that our meetings will be virtual at least through end of May so

our programs and speakers will be planned

The next virtul meeting will be on January 17th starting at 6.00pm

Topics will include a Virtual Workshop on Bench Vice and other ways of holding wood

details to be announced

Top

Guest Virtual Speaker

Chance Coalter

Veneering

Chance has taught veneering at Palomar College for a number of years. He often cuts his own veneers using his 18 inch Laguna bandsaw. His veneers are usually about 1/16" thick. He uses a Laguna carbide tipped blade that is 1-1/8" wide. The blade is expensive, costing about $240, but he has not had to sharpen it yet. He stressed the importance of buying a blade with the minimum number of teeth per inch.

He uses a vacuum bag to clamp the veneer in place while the glue dries. He mentioned that you could get started with a vacuum bag and pump for about $300.

When it comes to glue, he stated that Unibond 800 was his favorite, but it does not have a very long shelf life when compared to Weldwood Plastic Resin Glue. Weldwood Plastic Resin Glue comes in powdered form and will last forever as long as it is kept dry. He also uses Titebond III. Cure time varies depending on the glue used, but the cure can be accelerated by heating the area. He has thrown an electric blanket over the veneer to speed up the cure.

When doing a bent lamination, he will use clamps, because they can apply greater force than the vacuum bag. The vacuum bag can apply no more the 14 PSI (atmospheric pressure). A clamp can apply much more force.

He mentioned that vacuum bags are available in vinyl or polyurethane. He uses vinyl, which is easy to repair.

Chance showed us his favorite retractable knife for cutting veneer into irregular shapes - the OLFA knife with break-off segments. When the blade gets dull, break of the segment to expose a sharp blade. Replacement blades can be purchased on Amazon, search for "BD-50P". He also showed us a special scraper that he uses to smooth a bandsawn surface.

He showed us one of the forms he uses to create a curved door. The form had grooves cut into it to facilitate airflow when used with a vacuum bag. He has used window screen with the vacuum bag to facilitate airflow.

Next he showed us the EDGETECH sanding disc for the tablesaw. He uses it to dial in the veneers to the exact width he wants. The Edgetech disc requires that you tilt the tablesaw at a 2 degree angle.

One of the things he said was critical to good veneer cutting on the bandsaw was to make sure the bandsaw table miter slot is parallel to the blade, and make sure the fence is parallel to the blade. Adjust the table in much the same way you adjust a tablesaw miter slot to be parallel to the blade.

Michael Fortune is the author of a good YouTube video on setting up a bandsaw.

https://www.finewoodworking.com/2011/04/07/how-to-set-up-a-bandsaw

Prisco Table

Wall cabinet with Ziricote veneer

Veneered Wall Panels

Chance's veneering work

Top

BAWA Toy Workhop

Coordinated by Paul Krenitsky

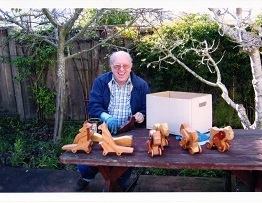

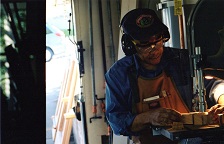

Paul showed us photos from past Toy Workshop events held at Bill Henzel's shop and at Jamie Buxton's shop. The photos included a number of past members who are no longer current members. Someone suggested we try to contact the past members and invite them to join us during our Zoom meetings. Paul was able to show us photos of the toys that Jon Kaplan, Jamie Buxton and Harry Filer made for this year's toy drive.

Ron Gerard

Pull Dinosaurs

Allen Harrison, Al Semenero,Ann Glyn, Gene Wagg,Tony Fanning, Bill Henzel

Allen Harrison

Per Madsen, Harold Patterson, Tony Faning, Fred Reicher

Gene Wagg and Ann Glyn

Gene Wagg's brother, Ann Glyn,Linda Slater, Tony Fanning, Glenn Wagg

8

Harold Patterson, Carl Johnson

10

11

Harold Patterson and Carol Reiser

GeneWagg, Harold Patterson, Crarol Reiser, George Comstock

Harold Patterson

Carol Reiser

Racing Cars

Treasure Boxes

<