Lloyd Worthington-Levy

Lloyd Worthington-Levy worked in machine shops while in high school, where he learned how to design and build various machined parts. This background in precision work carried forward when he began woodworking as a hobby after graduating from college. His work includes reproductions, designs based on historical styles as well as original designs.

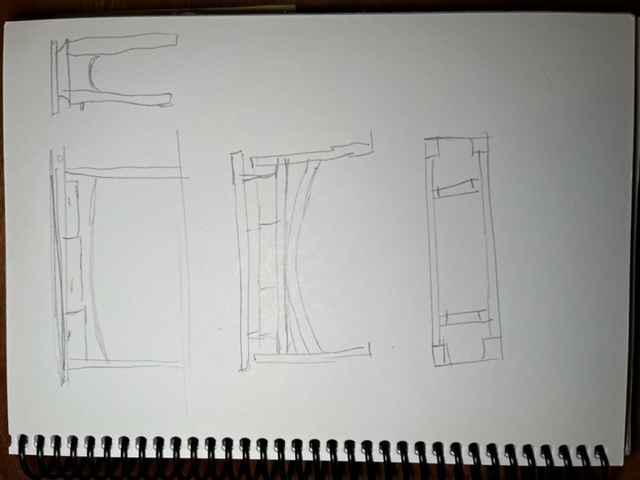

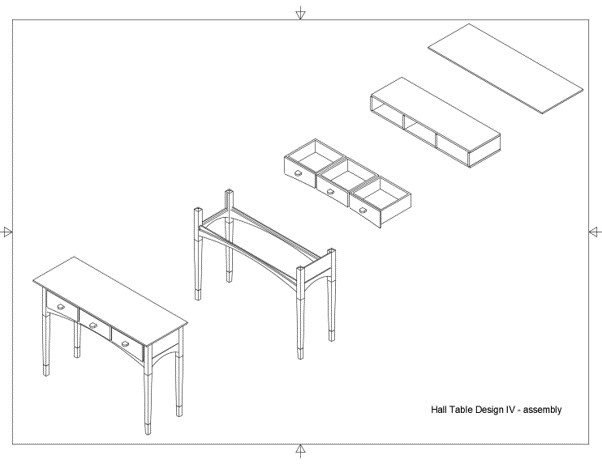

Lloyd uses Computer-Aided-Design (CAD) extensively. The design process for his original furniture starts with hand drawn sketches. The next step switches to a CAD program where overall proportions and dimensions are established. This CAD model is then refined to the level of individual parts needed to build the piece. Once this 3D model is complete, it is separated into drawings of individual parts.

Side table

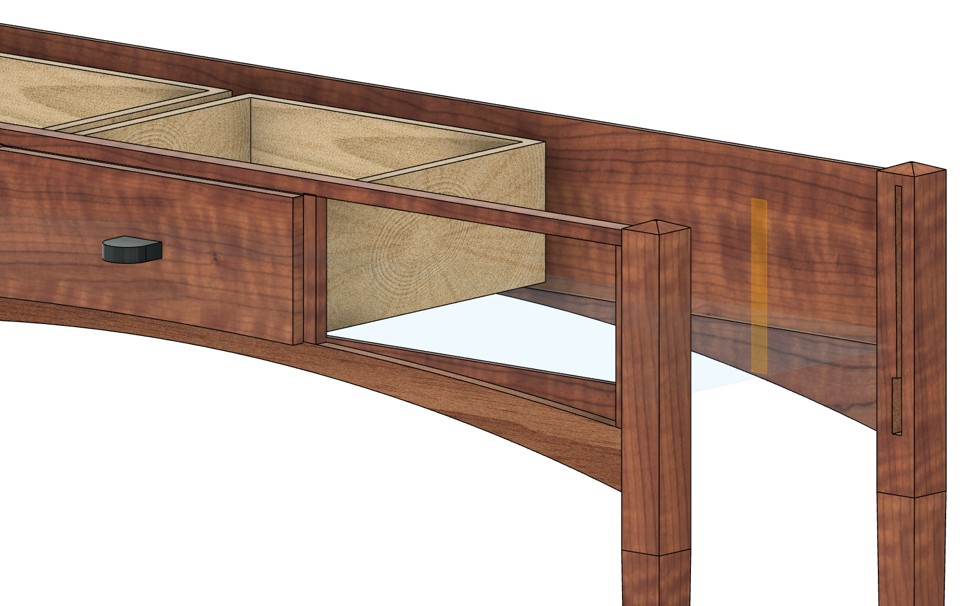

This is a Walnut, Cherry and Ebony side table that Lloyd designed in Fusion 360. Fusion 360 is a powerful parametric 3D design program that is free for users with limited requirements.

It allowed Lloyd to see what the table would look like before he cut any wood, and to produce fully dimensioned drawings of all the components.

The table has drawers, tapered legs and a floating Walnut top.

The drawers have dovetail joints. He cut the dovetails on his tablesaw. He has a tablesaw blade ground to 7 degrees just for cutting dovetails. He made a clever jig for cutting the tapered legs. The legs have about 3-1/2 inches of ebony veneer extending up from the bottom to give the illusion that the legs are not too long and spindly looking. The drawers slide into a frame made with dowel and Domino joinery. The legs have mortise and tenon joints that mount to the frame. With the exception of the Walnut top and Ebony lower leg veneers, the remainder of the table has cherry exterior surfaces. The drawer pulls are Viola tuning pegs.

Finish: General Finishes water-based polyurethane - 3 coats. Most pieces pre-finished prior to assembly.

Table made of walnut from Global Hardware Supply in Campbell.

Design process for creating this Sideboard

Sideboard in Greene and Greene style

This piece was inspired by the Greene and Greene style and includes square plugs, arched handles and cloud lift aprons.

Constructed with Cherry and ebony.

60 in wide 15 in deep 33 in high

Chest with Serpentine Front

The concept of a serpentine front for this chest grew out of seeing an antique piece. It is built with steam bent, laminated drawer fronts. Gradual drawer heights provide added visual interest.

Constructed with mahogany

21 in wide 16 in deep 21 in high