President's Message

Fellow woodworkers,

In today's world of electronics, social media and all things new, I have noticed an increase in wooden things for sale that enhance your home or your office. Most of them are very simple wooden structures with little in the way of traditional joinery or joints. Many of them are, of course, accessories for iPhones.

One of the less simple and more fascinating things:

CHINON Legato CH-PS840 Handcrafted Passive Speaker Dock

It looks beautiful and I am sure sounds good. Claims to be "Handcrafted from ash hardwood". Ash is used due to its "stable quality and excellent sonic performance".

But "Handcrafted"? - looks like a lot of handwork for $249

Handcrafted may mean hand tuned as the density of wood is not consistent so probably needs a rotary grinding to produce the perfect sound.

If any of you purchase one of these then I would love to see, and hear, it at one of our Show and Tells.

For more information: chinonshop.com

[As woodworkers you should look at the pictures of the horn and work out how it is made – an interesting challenge]

You can get many wooden cases for you iPhone ranging from $24 to one made of laminated Walnut and Maple at $89 and more. Case are available in Padauk, Bamboo, Redwood Burl even "reconstituted Ebony" and Recycled Skateboard. Many of them made in the USA.

Will the day come when we see an iPhone case at Show and Tell? Are any of them made without CCN machines?

See more at: carved.com

There are also iPhone docking stations

Routed channel for you cable

Live edged docks to go with your live edge table

With your left over bits of 2 x 4 you can make a Shanty Lamp which sell for only $40

Or if you want to make something a bit closer to traditional furniture making there is this Art Deco screen. See more at: slipperyskip.com

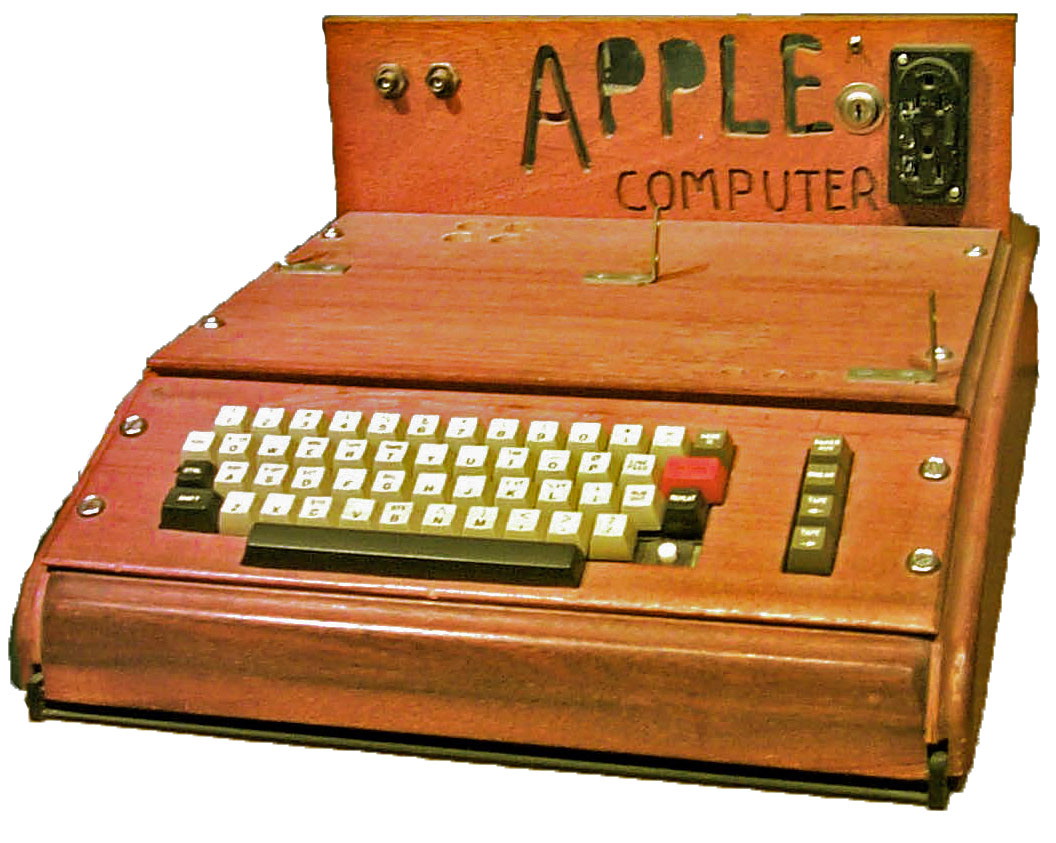

There are quite a lot of wooden computers available but they are not a really a new thing:

This Apple 1 computer from 1976 is now in the Smithsonian.

Note: I searched the web for the woodworker who made this historic box but have not been able to find a name. These computers were sold as an assembled pcb with some other bits and a manual. The one above has been customized with an after-market wooden enclosure with carved name, and keyboard. Steve Wozniak build all the early Apple machines himself but it is not clear if he ever made any of the boxes.The computers were sold by a Paul Terrell the founder of The Byte Shop and he had boxes made for some of the kits but probably just by an unnamed woodworker.

Japanese tool sharpening class

A couple of weekends ago a group of us attended a class at Chris Weiss's workshop where we spent the day learning how to sharpen Japanese chisels and planes. An interesting process, very different to the western tools we are used to.

BAWA Show

It is not too late to enter our show later this month. The show is always an amazing collection of projects made by our members and their guests. Tables, chairs, clocks, boxes, bowls, toys and sometimes structures you never thought you would see at a woodworking show, like a working gear box or a piece of sculpture. You can get in the mood for the show by going to our website and looking at the galleries of our previous shows.

See entry details and times etc.: For details: Show info

Enjoy your woodworking

Frank (Contact at: Frankramsay8@aol.com)

Frank Ramsay brought the meeting to order at 7 pm.

New Members and Guests:

Don Nguyen came as a guest. He sells large slabs of domestic wood. Curently he has walnut, tiger maple and maple burls.

Announcements:

The Wood Show 2014 is rapidly approaching. It will be held the weekend of October 17-19 at Woodcraft, San Carlos with the reception being held there Friday evening. Show entries must be delivered to Woodcraft Thursday afternoon or early Friday morning. We need volunteers for the show, to staff the information booth and for set up and tear down.

There will be no October meeting.

The November meeting will include the annual election of officers for the club. The judges from the Wood Show will review and critique the show entries.

The December meeting will be preceded by a BAWA board meeting at 5pm, followed by the regular meeting with the annual hors d'oeuvres.

Chris Weiss, tonight's featured speaker will be hosting a Saturday seminar on tuning and using Japanese chisels and planes on September 27. It will be held from 10am to 4pm in his Oakland Shop. He is offering three different Japanese tool packages available from Hida Tools in San Francisco.

Harold Patterson is conducting a Toy Workshop at Jamie Buxton's shop on September 27.

Stan Booker is raffling off an 8/4 maple plank, 9 feet long, 10 inches wide.

Frank Ramsay and Bruce Powell are exhibiting at San Francisco Open Studios again this year.

Neal White has donated two items to the Silent Auction: a cordless sander (you need to put a cord on it) and an electric drill on steroids.

Chris Weiss

Chris Weiss is joining BAWA once again, this evening to talk about Japanese Tools and Sharpening Techniques.

Chris started his presentation with a tool overview, explain how to choose the various tools needed.

Layout Tools:

Layout tools include layout squares, marking gauges, hammers, Camilla oil with pad and an ink well.

The layout squares come in two sizes and are used in conjunction with the ink well. The square can be trued to square by tapping at the leg intersection joint.

Marking gauges are made with single or double adjustable length shafts. The marking cutter is made with steel blades. Wedges or screws can be used to fix the shaft position.

The head on a hammer usually has one flat side and one rounded side. The flat side is used with chisels, the round side is used to driving nails and to express wood. The handle length typically is tailored to be the same length as the users forearm.

Camilla oil with pad is used on both the steel and wood of all tools.

Chisels:

There are two types of chisels: cabinet makers' chisels and timber framing chisels. Cabinet makers' chisels are smaller and have a steel ferrule at the top of the handle to prevent the wood from splintering when struck repeatedly with a hammer. A mushroom forms.

On the back or flat side of the chisel there is always a single, double, or even a triple hollowed groove(s). The purpose of the groove is to help to clear wood debris from the cut and to track better. The groove stops before the cutting edge, leaving a flat surface for sharpening. The steel is always laminated with a softer core and a hard outer layer. Blue steel is the most expensive, is more brittle and requires more skill to sharpen. However, it produces a superior cutting edge.

Chisels have to be tuned for use right out of the box and there is a break-in period of early use, while the tool and user adapt to each other.

Handles can be made of red or white oak, and boxwood is the best. Heartwood is preferred.

Planes:

The block of the plane can be made of quarter sawn white or red oak. All planes must be tuned out of the box. The first step is to lap back surface of the blade flat, typically using water stones. The chip breaker must be flush with the blade across its full width. Japanese planes are held backwards from a western plane and cut on the pull stroke. Once the plane is finely tuned it is possible to get a finished surface with one pass of the plane. A clean cut will close the wood pores, imparting a lustrous polished surface that has improved water resistance. Sanding, in contrast, open the pores of the wood and creates more surface area.

Typically three planes are used together is sequence. The difference is in the depth of cut. All blades are rounded slightly at the edges to reduce edge tear out. You can distinguish the soft gray steel by its speckled appearance.

The sole of the plane block has two areas of slight concavity (1/64"), one in front of the blade and one behind the blade. The sole is flat at the front, back and at the blade.

Good planes will be signed and have laminated steel in the blade and chip breaker.

Other types of planes include spoke shaves, rabbet planes, dado planes, side cutting planes and chamfer planes.

Saws:

Japanese saws cut on the pull stroke, not on the push stroke that characterizes western saws. Pull stroke saws can therefore be made thinner with finer cutting teeth. Rip and cross cut saws have different tooth patterns. Saw blades can be reinforced with a steel back rib or left bare and flexible. Inexpensive saws are stamped out, expensive ones cut by hand. Signs of a good saw include the bluing found on tempered blades, hammer marks indicating hand straightening of the blade and a signature. The blades for hardwood saws have teeth that are more vertically oriented.

Sharpening:

Chris uses water stones to sharpen his tools. However, he has a carborundum stone that he uses for flattening his water stones. Alternatively, he could use a steel or glass plate with wet/dry sand paper. He also has a dedicated diamond stone for flattening.

The first or coarsest stone to use is the Red or 800-1000 grit stone. The next stone to use is the Yellow or 1000-1200 grit stone, followed by the White ceramic stone with a grit texture of 1500. The final stone is the natural stone with a grit texture of 4000. Stones must be saturated in water before use.

Recommended Books:

Chris recommends the following books:

Japanese Woodworking Tools—Toshio Odate, $20 Amazon

The Art of Japanese Joinery—Kiyosi Seike, $19 Amazon

Encyclopedia of Wood Joints—Wolfram Graubner, $85 Amazon

A mock-up of a stair rail incorporating a Japanese style joint that Chris showed.

As the time limit approached, Chris drew his presentation to a close and we moved to a Show and Tell. Another great program; just scratching the surface of Japanese Tools.

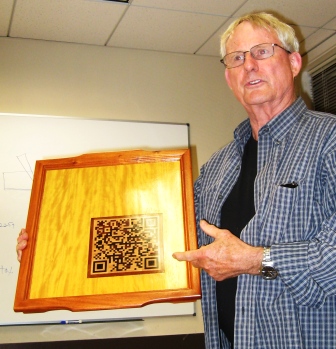

Bruce Powell brought in a tray he has made that will be shown at Open Studios. He calls it the QR reader Tray because it has a marquetry QR digital image in the center of the tray. He challenged us to read it and only after a frantic app search on the web were we able to download a CR reader and translate the dots to English. We offer you the same opportunity—read the image on the photo you see here.

John Blackmore

Secetary

johnblackmore@comcast.net